Using this multicell charger, you can safely charge up to two pieces of Ni-Cd cells or Ni-MH cells. The circuit is compact, inexpensive and easy-to-use.

Using this multicell charger, you can safely charge up to two pieces of Ni-Cd cells or Ni-MH cells. The circuit is compact, inexpensive and easy-to-use.

Multicell Charger Circuit

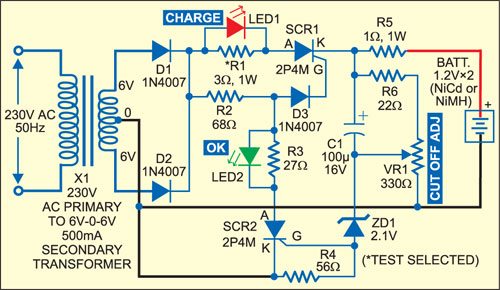

The 230V AC mains is down-converted to 12V AC (at 500 mA) by step-down transformer X1, converted into pulsating DC voltage by diodes D1 and D2, and fed to the battery charger terminals via current-limiting resistor R1 and silicon-controlled rectifier SCR1.

SCR1 is at the heart of the charger. Normally, it conducts due to the gate biasing voltage available through resistor R2 and diode D3, and the battery is in charging mode, which is indicated by LED1. Resistor R2 limits the charging current to a safe value. Charging current of this circuit is about 250 mA.

When the battery reaches full charge, SCR2 conducts to pull down the gate of SCR1. This state is indicated by LED2. Now remove the cells from the charger. Normally, Ni-Cd cell with a rating of 500 mAH will take around 2.5 hours to reach full charge, while the charging time for Ni-MH cell with a rating of 1500 mAH will be around 7 hours. Charging time may vary depending on the settings of the charger and input supply line conditions.

Construction & testing

After construction, a minor adjustment is required for ensuring proper performance: Power on the circuit without cells and adjust VR1 such that LED2 lights up. Now measure voltage across the charger output terminals, which should be around 5V DC. Now insert the two cells into the holder and connect it to the charger output terminals for charging. LED1 instantly lights up to indicate the charging process. If LED1 glows dimly, readjust VR1 for proper glowing of LED1. Now the circuit is ready for use.

Use of a small heat-sink is recommended for SCR1.

The article was first published in August 2005 and has recently been updated.