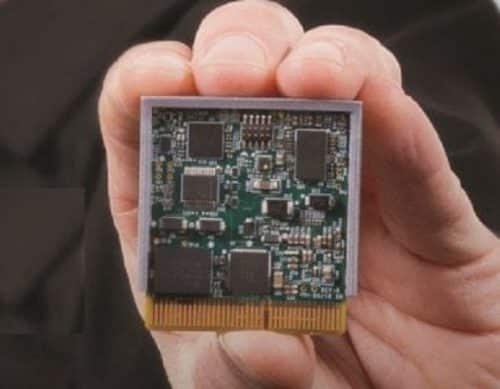

Here’s an ultra-compact PLC reference design that provides multiple software-defined I/Os in an ultra-compact (less than 1 cubic inch) solution, designed to increase productivity and reduce downtime in industrial and building automation applications.

The Go-IO reference design (MAXREFDES212) is a next-generation industrial IO solution that is designed to increase productivity, further adaptive manufacturing, and provide machine-level health and status information for making critical, real-time decisions.

To address the current trends of Industry 4.0, the design claims to meet stringent size and power demands. Go-IO packs 17 configurable IOs in a space one-half the size of a credit card. It is also touted to be a 10x smaller solution with 50% less power consumption compared to its predecessor, the Pocket IO.

Key advantages

- Compact Design

Ultra-small, compact footprint (< 1 cubic inch: 1.7in.W x 1.56in.D x 0.25in.H) allows Go-IO to be integrated throughout the factory floor - Robust, Safe Technology

Composed of advanced industrial products rated to withstand -40°C to +125°C - High Efficiency- Ensures a small energy signature to increase efficiency—no cooling fan is needed

- Packs a Powerful Punch

Offers a full suite of 17 IOs to control an entire manufacturing node or piece of equipment, including analog inputs, analog outputs, isolated digital inputs, digital outputs, IO-Link masters, and isolated RS-485 with integrated power - Programmable

Programmable via the MAX32630 using the low-power Arm®Micro toolchain

Intelligence and Decentralized Control - Enables automation equipment to act autonomously based on changing environments—as issues are identified, equipment can reprogram itself to do another task

- Productivity and Throughput Increases

Enables higher factory uptime by supporting the ability to quickly isolate problems

For more details on the reference design, click here.