The Bi-Directional EV On-Board Charger is the future of efficient EV charging, being compact yet power-packed and offering benefits beyond mere charging.

The evolution of electric vehicles (EVs) has ushered in a demand for more efficient and compact charging solutions. The Bi-Directional EV On-Board Charger (OBC) represents a leap, marrying power and efficiency in a compact design. This charger facilitates the rapid charging of EVs and offers a bi-directional power flow, allowing the vehicle’s battery to return energy to the grid or support home energy needs. Such capabilities address the growing demand for versatile charging solutions that integrate with the evolving smart grid and home energy systems, ensuring that EVs are consumers and potential energy contributors. Wolfspeed has launched the reference design for a 6.6 kW high-power density bi-directional EV on-board charger to simplify the design process. CRD-06600FF065N-K incorporates a SiC MOSFET, the C3M0060065K.

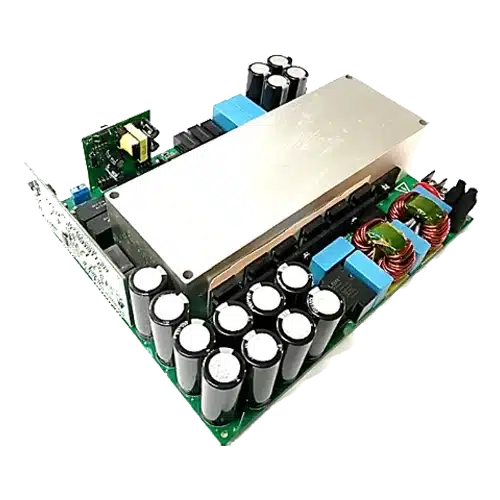

The reference design board is designed for isolated Bi-Directional EV charging systems. This board offers an isolated adjustable DC output by utilising a single-phase AC input, making it ideal for battery charging. However, for effective operation, this output should be linked to a resistive or electronic load, with the Constant Current (CC) mode being recommended. This is vital because the board doesn’t encompass a predefined battery charging algorithm. Moreover, in its Direct Current to Alternating Current (DC/AC) mode, signifying its discharge mode, the board is adept at providing power to a resistive load, but this necessitates the output being connected to a DC voltage source.

The OBC can function on a universal, single-phase input, delivering an output voltage between 250 VDC and 450 VDC. Depending on requirements, it can work in constant-current, constant-voltage, or constant power mode, and these parameters can be adjusted via a Controller Area Network interface (CAN) interface. Its initial AC/DC Power Factor Correction stage, adopting a continuous conductivity mode totem-pole bi-directional design, runs at 67KHz, leading to a DC link voltage. This voltage is then processed by a Bi-Directional Isolated DC/DC Capacitor-Inductor-Inductor-Capacitor (CLLC) resonant converter, operating between 148-300KHz. As the charging battery voltage oscillates between 250Vdc and 450Vdc, the DC link voltage adjusts from 385Vdc to 425Vdc, maximising the OBC’s efficiency. This innovative design enables a peak efficiency of 96.5% during charging and discharging. Both input and output segments of the DC/DC stage deploy a full bridge switch system segregated by a high-frequency transformer.

A uniquely crafted heatsink manages the heat dissipation of all power MOSFETs and power magnetics, boosting the design’s power density to an impressive 54 W/in3. While this unit is crafted for EVs, it lacks a built-in battery charging algorithm. When in DC/AC mode (discharging), it’s essential to use a resistive load for testing. In contrast, electronic and resistive loads can be employed in its AC/DC mode (charging), with a maximum output current restriction of 18A in charging mode.

Wolfspeed has tested this reference design. It comes with a Bill of Materials (BOM), schematic, etc. You can find additional data about the reference design on the company’s website. To read more about this reference design, click here.