EV charger reference designs enable manufacturers to scale solutions based on market demands, catering to both residential and commercial charging applications.

The reliability and performance of Electric Vehicle (EV) chargers are essential to driving global market adoption. EV manufacturers are focused on delivering robust, weather-resistant, and user-friendly EV chargers. Microchip provides the most active components for these EV charger reference designs, including the microcontroller (MCU), analog front end, memory, connectivity, and power conversion. This integration simplifies the development process, allowing manufacturers to bring new charging solutions to market more quickly. The company’s E-Mobility team is dedicated to creating reference designs that the customers can utilize directly. Their goal is to help customers shorten design cycles by offering comprehensive solutions like these new EV charger reference designs, along with the necessary hardware, software, and technical support.

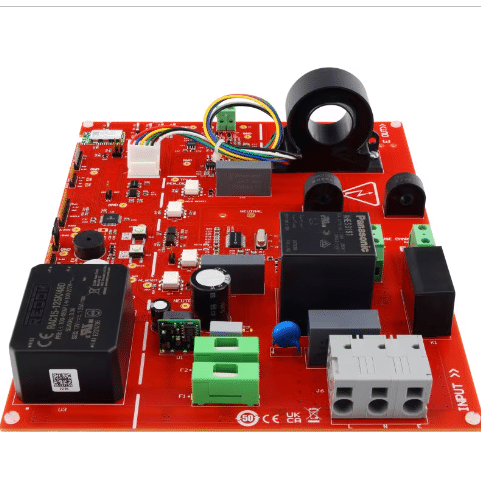

The Single-Phase AC Residential EV Charger Reference Design offers a cost-effective and convenient home charging solution using a single-phase supply. It includes a high-performance energy metering device with automatic calibration, simplifying production. Safety features such as Protective Earth Neutral (PEN) fault detection and Residual Current Device (RCD) detection are integrated into the design. This EV Charger reference design aims to achieve lower overall system costs for residential applications where only a single-phase supply is available. It features an AC energy metering function utilizing the ATM90E26 for enhanced reporting capabilities, reducing the processing load on the Arm Cortex-M0+ SAMD21 microcontroller unit (MCU) and facilitating automated calibration to ease manufacturing. The design also includes an integrated relay and driver, allowing expansion of charging capacity to 7.4kW.

The system utilizes a BM70 module for Bluetooth Low Energy (BLE) communication, ensuring seamless data transmission, including charging status reporting. Built on reliability and high integration, it features cost efficiency with most components sourced from Microchip. The ATM90E26 ensures accurate energy monitoring, providing precise power delivery and measurement to the vehicle. An onboard relay and driver offer flexible, safe charging, protecting users from hazards. Advanced connectivity and security are supported through dual secure BLE connections with a smartphone app and a full CP logic stack for reliable vehicle communication, reducing development time. Ready-to-use software with full functional source code allows for quick deployment. Key features include up to 1% accuracy with automatic calibration by the ATM90E26, Microchip-sourced components, a field-proven CP logic design, integrated safety protection, dual secure BLE connections, and a BLE smartphone app.

These designs come with complete hardware design files and source code, including tested and protocol-compliant software stacks. OCPP provides a standardized communication protocol between the charge point or charging station and a central system, ensuring interoperability across different networks and vendors. Microchip has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.