When it comes to low-power portable devices, why not rely on a single battery for the power? I see many such applications that require two or three primary batteries, which seems pretty wasteful. After all, by using a readily available, low-cost switching regulator chip, you can power your portable device with a single battery.

Multiple batteries, of course, increase the voltage. But you can achieve the same with a great, high-efficiency boost converter. What’s more, the converter will also maintain a nice regulated supply for the device. With the advantages in efficiency and small size, this really is a sweet application idea.

Suppose you need a 3.3V supply and want to extract as much energy as possible out of your battery. You could use a non-rechargeable, standard-type primary AAA or AA size battery. Comprised of alkaline or lithium, these batteries offer much higher energy density than any rechargeable cell.

Alkaline batteries cost about one-third that of lithium. However, since alkaline batteries have a higher internal resistance, they function better at low discharge rates. Also, at about 210Wh/kg, they have about one-half the energy density of 1.5V lithium primary cells (Li-FeS2). Under a high load, an alkaline cell’s output voltage will sag due to the high internal Z. A spent alkaline in a digital camera (a high peak load) will leave enough energy to run the kitchen clock for two years. The Energizer Ultimate Lithium brand is an example of a lithium Li-FeS2 type battery (1.5V), providing a 400WH/kg energy density and relatively low impedance.

A Closer Look at 3.6V Primary Lithium-Ion Batteries

Lithium-thionyl chloride (LiSOCI2 or LTC) is another kind of lithium battery that I’d like to highlight. While LiSOCI2 is not generally found in the drug store and is quite a bit more expensive than the Li-FeS2 type, it does provide an energy density of up to 500WH/kg. With a nominal voltage of 3.60V/cell, it is also one of the most rugged of the lithium-metal batteries. LiSOCI2 cells offer an even higher energy density than the 1.5V Li-FeS2 type.

I also must mention that the LiSOCI2 3.6V batteries are available in bobbin and spirally wound versions. The bobbin-type have higher internal impedance, but provide a higher energy density and a very low self-discharge rate (<1%/yr). As a result, the bobbin-type can operate up to 40 years in a very low-current application.

The use of 3.6V lithium-ion batteries has become common. However, because the battery voltage ranges between 2.7V and 4.2V, a step-up/step-down DC-DC converter is needed to make a standard 3.3V supply.

While there are various topologies that can be used for a combination step-up/step-down converter, the most popular is the single-ended primary inductance converter (SEPIC). This is a non-isolating voltage converter that is unusually non-inverting, though it can also be inverting.

Another method that many don’t consider is using a step-up converter followed by a low dropout (LDO) regulator. Because a linear regulator is used for the step-down function, many assume that it has poor efficiency. However, when making 3.3V from a single lithium-ion battery, the efficiency of this circuit can exceed that of an equivalent SEPIC circuit.

There are also the added advantages of lower component count, lower cost, and less board space.

Boost Regulators with Ultra-Low Quiescent Current

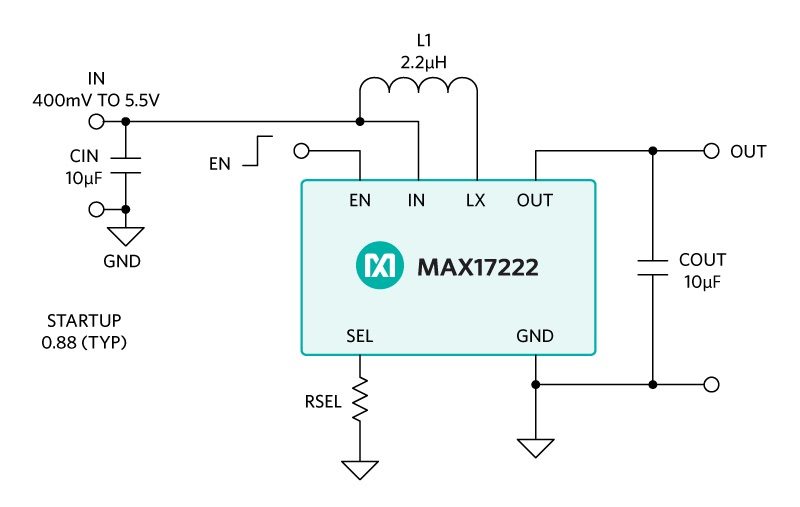

As an example of a boost regulator that can support single-battery portable devices, let’s consider the MAX17220–MAX17225 family of boost (step-up) DC-DC converter ICs from Maxim. Figure 1 provides a circuit drawing. These ICs offer 225mA, 0.5A, or 1A peak inductor current and feature a 0.40V minimum VIN. They have ultra-low quiescent current and a True Shutdown mode that disconnects the output from the input without forward or reverse current. Their output voltage is selectable with a standard 1% resistor. Since the converters have a built-in power switch, the circuit design requires only four external components.

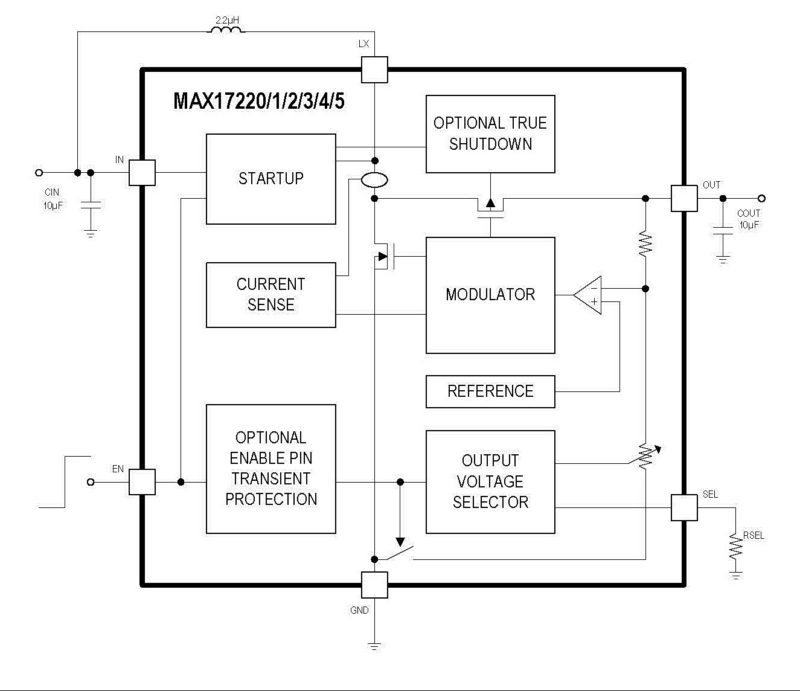

The MAX17220-MAX17225 converters are suited for small, battery-powered portable designs because they come in a very small total solution size and provide high efficiency (up to 95%) throughout their entire load range (see Figure 2 for a block diagram). Their switching frequency is up to 2.5MHz, and their low quiescent current helps extend battery life. For easy PCB layout, they are available in 2 x 2mm 6-pin μDFN or 0.88 x 1.4mm 6-bump WLP packages.

Another boost regulator example may be found in the MAX1705 and MAX1706 family of high-efficiency, low-noise, step-up DC-DC converters with an auxiliary linear-regulator output. As discussed previously, 3.6V lithium cells typically require a buck-boost topology to cover their lifetime voltage range. These converters, however, combine boost and linear regulators, and the linear output is a very low-noise supply as well. Using a 300kHz synchronous rectifier PWM boost topology, the ICs can generate a 2.5V to 5.5V output from a battery input, such as 1 to 3 NiCd/NiMH cells or 1 Li-Ion cell. They provide a regulated output over their entire operating voltage range. The MAX1705 has a 1A n-channel MOSFET switch, while the MAX1706 has a 0.5A switch. Minimum VIN is 1.1V and they have a 1μA shutdown mode.

The linear regulator in both devices delivers up to 200mA. An efficiency-enhancing track mode reduces the step-up DC-DC converter output to 300mV above the linear-regulator output. Compared to similar non-synchronous converters, these converters provide 5% better efficiency. To enhance efficiency at light loads, they feature a pulse-frequency-modulation standby mode. Both devices come in a 16-pin QSOP package and have two shutdown-control inputs for push-on/push-off control, along with an uncommitted comparator that can be used as a voltage monitor. To evaluate the ICs for various battery-powered designs, you can check out the MAX1705 evaluation kit.