Solid-state lighting is rapidly becoming the most popular lighting option for a broad range of applications. With the U.S. government’s mandate to save energy, incandescent lamps are being rendered largely obsolete, and increasingly being substituted by Light Emitting Diode (LED) bulbs. LED bulbs offer a better choice for many applications due to the ease of adapting them to many different socket and shape requirements, as well as their long lifespan (typically 25,000 hrs.). As prices for LED bulbs continue to fall and become more competitive with compact fluorescent (CFL) bulbs, analysts estimate that LED lighting’s share of the residential lighting market will reach nearly 50 percent in 2016 and more than 70 percent in 2020. For designers, however, it’s important to understand that LED lighting and dimmer controls present new challenges than previous technologies.

Triacs, or triode for alternating currents, comprise the heart of AC light dimming controls. When triggered or turned on, these components can conduct current in either direction. Previously, triacs used in dimmers had typically been characterized and specified for incandescent lamp loads, which feature high end-of-life surge current when a filament ruptures, as well as high current ratings for both initial high in-rush currents and steady-state conditions.

Compared to incandescent lamps, LEDs have much lower steady-state current, and their initial turn-on current can be much greater for several microseconds at the beginning of each half-cycle of AC line voltage. On average, the steady-state follow current is less than 100mA; the current spike for an AC replacement lamp is 6–8A peak.

LED bulbs for residential lighting might draw 7.5W (A19 bulb-450 lumens) or higher, with a chandelier typically using around four to ten bulbs, while a string of 50 holiday lights could use as little as 4.8W. Old filament units for recessed ceiling fixtures generally draw 65W, while an LED flood lamp designed to replace the typical filament unit produces 750 lumens but consumes only 13W (BR30).

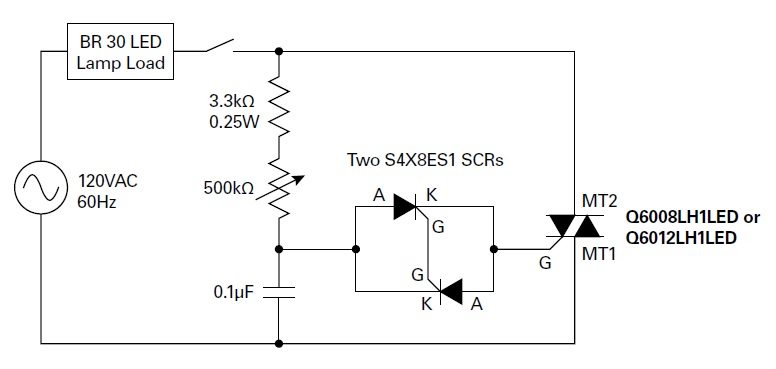

The newest generation of triacs makes designing an AC circuit for controlling LED light output less complicated than previous application as fewer components are required: a firing/triggering capacitor, a potentiometer, and a voltage break-over triggering mechanism. By utilizing two inverse parallel sensitive gate silicon-controlled rectifiers (SCRs) as the voltage break-over triggering device, it lets the controlling circuit yield a broad range of light level outputs. This helps achieve a low hysteresis control because the two SCRs can then form a full breakback trigger. See Figure 1 for an illustration of a circuit diagram for a recessed flood lamp (such as a BR30 LED lamp) suitable control.

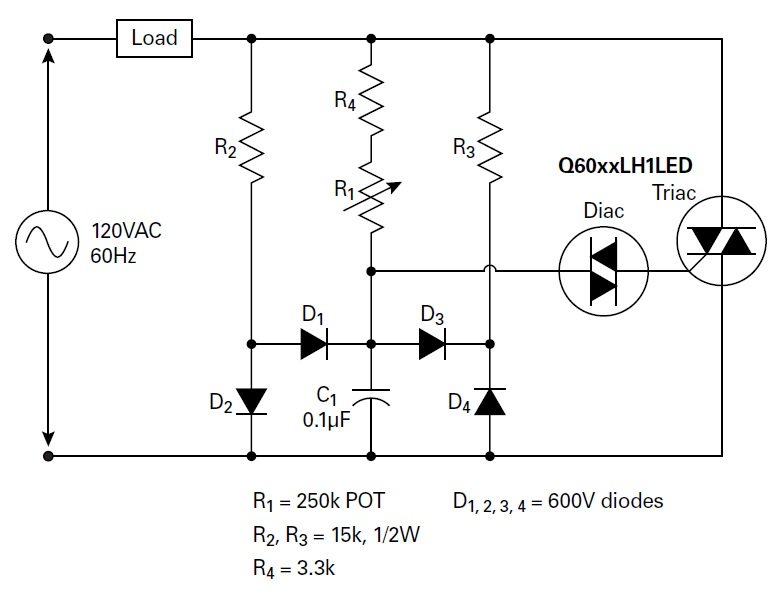

This circuit allows the bulb to turn on at nearly the full 180° on each AC half-cycle; the RC timed turn-on also may be delayed to a small conduction angle on each half-cycle for very low light output. Triacs featuring low latching and holding current characteristics, such as the Littelfuse Q60xxLH1LED Series, allow the triac to remain functional at very low current levels. Two inverse parallel sensitive gate SCRs (S4X8ES1) with their gates tied together produce a significantly low voltage triggering device with full breakback voltage, producing little hysteresis and allowing the potentiometer to be set for a small conduction angle with turn-on being immediate when the line switch is turned off and on. The diagram in Figure 2 adds steering diodes around the C1 firing capacitor, improving upon previous phase control/dimmer circuits that had poor hysteresis.

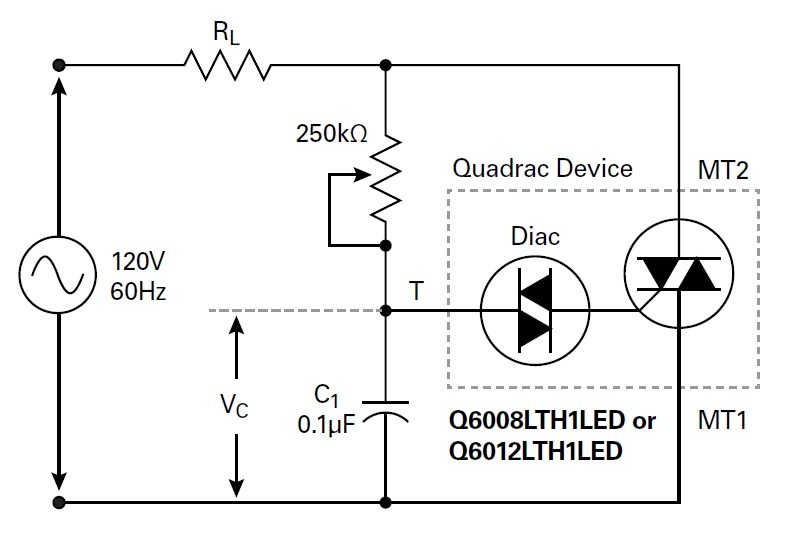

A quadrac device (a unique type of thyristor that combines a diac and a triac) offers a simple variable light control alternative for applications in which low hysteresis and a wide control range are less critical. Figure 3 illustrates how combining an alternistor triac and the diac triggering device in a single TO-220 isolated mounting tab package can reduce the component count further. This control circuit confers a little lower full turn-on voltage due to higher VBO switching of the diac trigger device but provides a dimming function that functions from 175° to <90° of each AC half-cycle.

For more details on LED lighting dimmer design, download the free application note available from Littelfuse.

About the Author

Koichiro Yoshimoto is Manager, Thyristor Business Development Manager for the Semiconductor Business Unit of Littelfuse, Inc. His responsibilities include identifying and developing strategic growth markets as well as introducing new products into those markets for power control products, focusing in Thyristor products. He received his B. Eng in Industrial Chemistry from University of Tokyo in Japan. He has been with Littelfuse for over 10 years and in the electronics industry for 20 years.

I want to communicate with Koichiro Yoshimoto how can I do this?

thank you

great article!

can we place a motor insted of a led as a load ? if not what modifications should be done on the circuit?

Is this dimmer noise free like hmmm after connect with ceiling fan