We, humans, are capable of handling things that we have never seen before. When we look at an object, our brain immediately knows how to pick it up—whether to use our palm, or just fingers, or maybe both hands! This sort of intelligence is what is lacking in current robotic systems. CynLr, a Bengaluru based robotics deep-tech startup founded in 2019, is now solving this problem by building visual object intelligence for industrial robots.

Robots working in the real world need to exhibit visual intelligence, or the capacity to employ their vision system, reasoning mechanisms, and prior knowledge to make sense of their surroundings—that’s real intelligence. “According to the field of cybernetics, intelligence is the outcome and not the source or cause. It is the ability of a system to self-regulate and handle a sophisticated situation,” says Gokul N.A., Co-founder and CTO of CynLr. This is why the founders named the company CynLr, which stands for Cybernetics Laboratory.

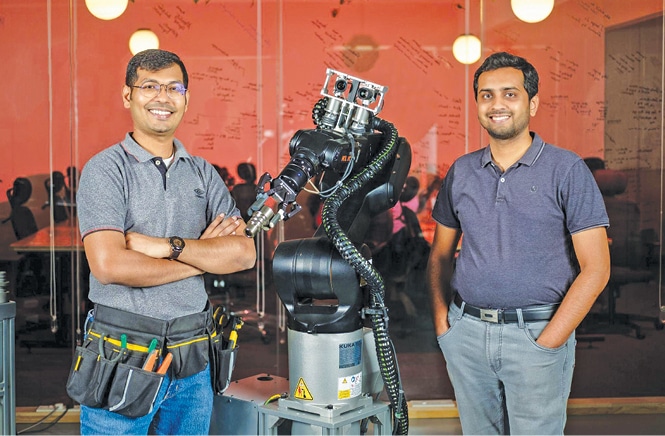

When the founders were working at NI, they realised that the existing machine vision systems were only successful for simple identification problems. These machine vision systems were not meant for industrial robotics applications. They could not be used by robots to correctly grasp objects, pick, re-orient and manipulate them, and make proper placements in an industrial environment. Imagine a pick-and-place robot that’s not able to grasp an object it’s supposed to pick! “We left our jobs and approached customers we knew had a problem to be solved,” recalls Nikhil Ramaswamy, Co-Founder and CEO of CynLr. “We ended up solving over 30 unsolved machine vision solutions that involved some kind of manipulation!”

For a robot to handle an object, it needs to consider a lot of parameters: not just colour, but also weight, texture, depth, shape, and much more. But current vision systems have reduced and abstracted it to just a colour pattern. That’s the difference between sight and vision—sight gives you a certain amount of data on a 3D object, but vision gives meaning to that data. CynLr’s technology actually enables vision. It allows robots to grasp any object without prior training. Because of this, robots can learn to operate items in any orientation, in addition to grasping objects in unstructured environments.

To turn their vision (pun intended!) into a product, the founders did hardware product design along with standardising their algorithms and paradigms. “One of the taglines that we write on our walls is: Hardware is a part of the algorithm,” says Nikhil. Today, CynLr has a dedicated hardware stack and software layer. On the hardware side, the company is the only one providing depth perception system in the world that has robotic eye movement, convergence, divergence, precision control, etc, that’s enabled through hardware.

“For our customers, we provide the whole system—a robotic arm equipped with vision with complete sophisticated grasping capabilities, so that it can handle objects,” says Gokul. Their tech can be applied in part tending, part assembly, and part inspection. The company is open to partnerships—both application partnerships and technology partnerships. Moreover, CynLr is actively hiring for multiple roles. In the near future, CynLr plans to step up its commercialisation and expand abroad. Apart from the automobile industry, they also plan to expand to other domains like logistics and electronics assembly.

To read the full interview about CynLr: click here