Demand for food has increased with global population explosion in the past few decades, making old farming practices obsolete. Improper fertiliser distribution over an agricultural land results in excess fertilisers available for weeds. To increase yield, precision agriculture was introduced where technology is applied to optimise productivity. Starting its operations in 2017, Europe-based Augmenta, founded by Dimitri Evangelopoulos and George Varvarelis, is one such startup that leverages latest technologies like deep learning to develop fully-automated yet sustainable precision solutions for economically boosting agriculture worldwide.

The name Augmenta has been created from the term augmented farming, which is used to define a combination of augmented reality (AR) with precision farming that can provide such precise information as leaf pattern/number, fungus appearance, height of plants and so on.

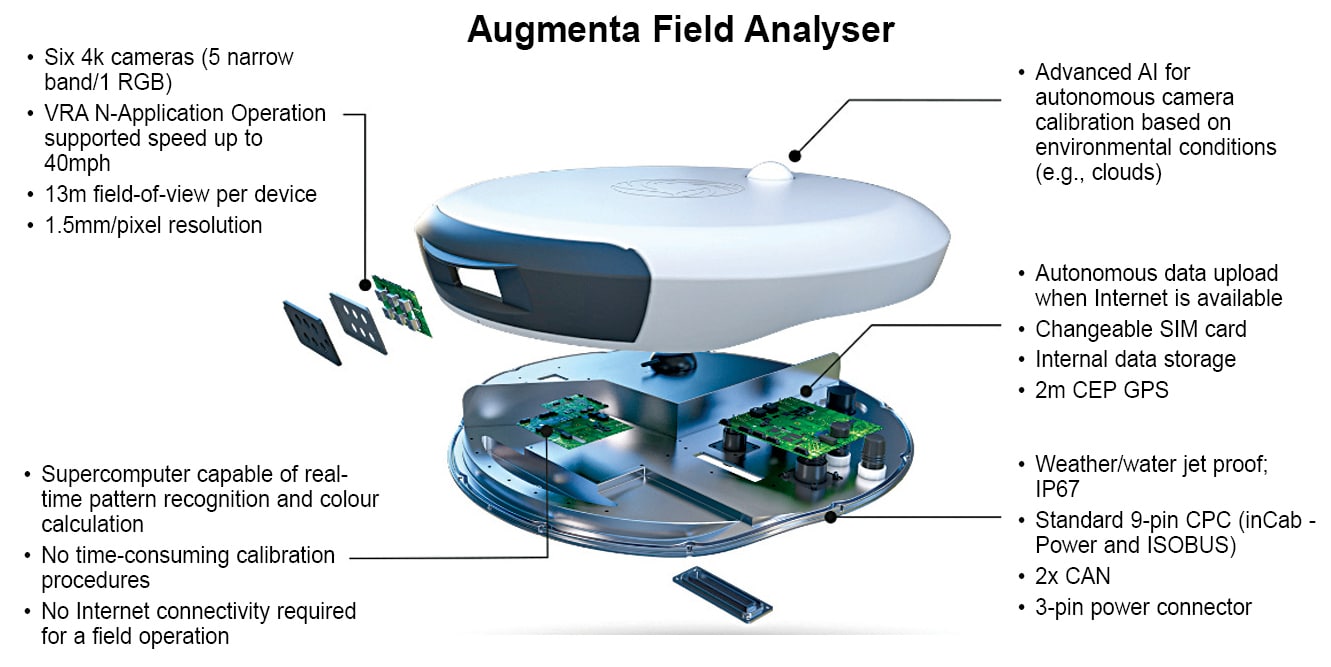

The company offers an artificial intelligence (AI)-based solution consisting of a hardware device and a Web platform for superior efficiency, thereby increasing the farmers’ income. During prototyping phase, the device was tested to perform in varied environments and conditions. The final product—the field analyser—is an Isobus-compliant plug-and-play device, which, when attached to a tractor or retrofitted to a pre-existing equipment, can scan and analyse crops like wheat, rice, canary grass and potatoes to ascertain the optimal quantity of inputs (fertilisers, pesticides and the like) required per unit area, as well as the timing of field treatments. For this, the device captures 4k video data using its multispectral cameras, and applies real-time image processing along with AI to measure canopy shape, size and light reflectance before applying inputs.

The Web platform uses visual data analytics to not only track real-time operations for performance but also make customised decisions for every farm for the future. Available information includes health index maps, crop input statistics, 4k images of damaged areas, etc.

Real-time monitoring of tractor position, speed and rate of application is also available given that a cellular connection exists. There are options to interface with the machine (sprayer or spreader) and control variable rate applications from it using deep learning algorithms to apply the correct amount of these inputs at the required place in real time.

The latest software update offers a host of new features including virtual fertilisation map generation, shapefile generation and downloading, unit customisation and choices between measurement units.

Benefits include increased yields, better grain protein levels and improved quality with lesser chemicals/fertilisers and input spend, unlike conventional methods. The process is less time-consuming and less labour-intensive.

Besides absence of noise, cost gets reduced when compared to drone/plane imagery and active sensor systems. Real-time processing makes it possible to avoid delays between data acquisition and usage.

Several data-based pilot projects have been completed with businesses, such as cereals grown for Italian multinational food company Barilla. The startup also partnered with NVIDIA last year for development of its cutting-edge deep learning device. The device already operates in numerous countries like Serbia, Turkey, Germany, the US, Brazil and Australia.

i agree with few points that are mentioned in deep farming using technology but i suggest to innovate something like using AI for organic farming

Good Information but i want to add one thing, The coming time is for organic farming and agriculture robots will also play a very important role in farming.