Xellier Networks, pronounced as ZAY-lier, is an India based company providing the next generation of high-tech security solutions for consumer spaces.

Q. What is the basic technical problem that you’re trying to solve with the product?

A. The big problem that we are trying to solve here is visual security. When we think of present security systems, we imagine a room with multiple cameras so that we can record if there is any theft event or burglary or something like that. And the problem with this system is that one needs to be on a continuous guard. One person is appointed to just look at the screens and interpret what is happening, to just navigate across 30 screens. It is physically very tiring and at the end you cannot hold the person accountable in case he missed anything. Bigger companies can afford professionals to do the same but the smaller companies or businesses cannot choose to do the same. Not only businesses but private properties as well.

We thought there needed some intelligence to be added in this process and that was our spark. With the development and advancement of technology and machines we can train the machine to detect and alert if something has happened and inform the manager or the one in charge. We aim to solve this problem.

“ Automation is a huge space and eventually the company that is going to stand out will be the one who is running AI into these devices.”

Q. How did you come with this idea? What is the story behind Xellier Networks?

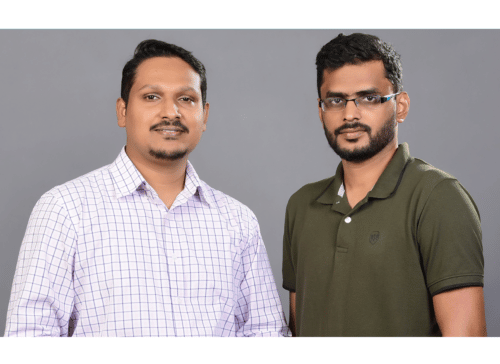

A. The story actually begins back when we were in our final year of college. We both are engineers and share the same curiosity. But we had our own commitments at that time. We then progressed with our respective lives but eventually we came across that feeling to start something of our own. The concept of entrepreneurship was very taboo at that time. So later after ten years of job and meeting our commitments when we met in 2018, we shared the same feeling and frustration.

We wanted to build something, so we had a discussion and began with all the planning. I remember being fascinated by the concept of home automation. We began our research related to home automation and we found out that home automation is quite a huge space in itself. It seemed like only the big companies stood a chance, as it would be a commoditized product world after all. The only possibility was to come up with a very unique or cutting edge technology.

Home automation requires a lot of investment. We cannot just start with buying a big piece of machinery and start making a sale from it, and eventually one product is not enough for home automation. One needs to cover all aspects of the home and automate it. So, just a motion sensor or a door opener or a curtain opener/closer product was not enough for the consumer. On the other hand, the R&D required is huge, unless you buy products from China and resell them here under your own brand.

So again we had a discussion on how to stand out. We came across something on the future of automation and AI based homes. And it sparked my interest, vision based products are something that can stand out. So we began our research and stumbled across the CCTV technologies.

But we did not want to build just another CCTV camera. Chinese companies are flooding the market with CCTV cameras, and American companies on the other hand are already developing intelligence in those cameras which we are planning. Whereas the Indian market is very tight with basic CCTV cams, although it is huge it cannot be covered by those foreign companies. This convinced us to develop an intelligent security system for the Indian customers.

Q. How did you build your first prototype? Can you share your product development journey?

A. We registered our firm in November 2018, and began our engineering research on how to put together our first prototype. Typically, you would go to a Semiconductor firm and get a reference design, but it didn’t exist at that time. There was no ready made solution that we could just take and build our software on it.

So, we had to build our own reference design from scratch. We put together some of our own money that we had saved over the years and decided to approach vendors to procure components. We wrote down features and use cases that we needed to support in our product and began developing it.

Right from the start we had a clear intention to productize our vision, so we recruited a design firm to help us visualize our idea and to ensure that our electronics fit well into the mechanical design. This exercise took time, but was worth it. We used various technologies like 3D printing, CNC milling etc. and ran through multiple iterations to visualize our perfect prototype. It was tough because all this was taking time and costing us a lot of money which we didn’t have much. We hadn’t raised any external money, so it was quite painful. We persisted until we were satisfied with our prototype.

Q. Can you share details about what challenges you faced on this journey?

A. We started with the idea of developing our own software on a standard camera hardware platform that we thought we could leverage but we ended up designing our own reference design. That was hard because we had to talk to many electronic component distributors, semiconductor suppliers and many didn’t want to support us because we didn’t appear to buy a million pieces. Also, many of the components that we use in our product prototype were also not available on electronic e-commerce websites. So, we had to talk, and persuade them to give us an opportunity in exchange for no support from their end. So it was less risky for them. We assured them that we will not ask for support as long as their documentations are perfect. Thankfully, they supported and that model worked for us.

Then the next challenge was to productise this prototype that we built. That was a whole new game in which we had no prior experience. We had to learn about the plastics, the materials, metals, etc. Many times, we had to contact the material supplier and ask them basic questions such as, is Polycarbonate better than ABS? Our design team was of the opinion to manufacture this product in China where they have the expertise and they would take care of everything. After months of discussions and deliberation, we decided to take quotes from the Chinese manufacturers. We were not that impressed with the pricing. It wasn’t really that attractive as the hype or the perception we had about china pricing.

We went to the drawing board again on how we want to scale up and plugged in the numbers to understand the economics. We understood that China is cheaper only when you produce in millions and more. So, we abandoned that effort to produce in China and began our study about how to produce this product here in India. We made a list of potential injection mould making companies that we could approach and began sending them RFQ’s. We hoped that would get an overwhelming response, but to our surprise only 2 people responded. That was very disappointing. We tried to call each one of them over phone numbers listed on their website, Justdial and connected with them via numbers listed on Indiamart. Very few people picked up the call.

We were losing patience by then. We assumed that they are not taking us seriously, so we decided to drive down to their offices in different cities. We took a traditional approach, and we personally reached out to the company MDs. We told them that we are not middlemen, they had assumed we are. We are the OEMs, we are manufacturers, we have a design. We want you to produce for us because you had to make the injection mould. So like that it was hard to convince them and then after we got their attention. We were totally surprised to learn that the plastics and metal industries were so cut off from the IT world. There was a generation gap between us and them.

In each of our visits to these plastics and metal fabrication firms, one thing we understood clearly was that these folks are capable of building really complex components out of India. And strangely, many of these products are all exported. That learning was enough for us to be convinced that we must produce in India. We convinced them to take up our project. We didn’t negotiate prices and paid them within 10 days when the Industry standard was Net 90 days. That’s the price we paid to get attention.

Now that the orders were placed, our next big challenge was how to validate the plastics and mechanical design. It was a challenge at a whole new level that we didn’t anticipate earlier. We spent weeks to months learning how to validate the design using 3D modelling, scanning, and CEM techniques. That really helped. We went through many iterations, which was really-really physically tiring.

By the end we got our final injection moulded samples, we had completed three years of operation. We still pushed forward, persisted because we believed in the technology we were creating. So finally in April 2022 we began our sales.

Q. Can you highlight a product that your company specializes in?

A. One of our key featured products is the Epic Cam which is a wireless AI camera. This camera is built on the concept of Sensor fusion mainly for the vision and audio, we also have thermal sensors which try to make a decision about whether a person is moving or a certain event is happening or more.

We have an artificial intelligence mechanism that is built inside the product which communicates with clouds. A combination of sensors gets some input and processes it to understand whether there is a person in front of the camera and once the camera knows that there is a person in front of it takes a picture of that person will send an alert to the user along with the high resolution photo within two to three seconds, wherever he is in the world.

Epic Cam also supports Vehicle and pet detection and alerts you immediately with evidence based alerts. And then the customer does not have to worry about storage. Video data is actually heavy data, it goes in gigabytes. We don’t want the customer to face any challenge so we provide a cloud storage option. Customers can directly keep an eye from their smartphone and download it remotely as well. The system provides access to past video data even when the camera is offline. It is basically a very versatile system.

“We believe that technology has to adapt to humans and not the other way around.”

Q. What are your plans for expansion in India and even abroad?

A. Currently, we are focussed on the India market. We are focussing on strengthening our technology and making it more robust. Besides, we are focussing on marketing and getting the word out about the product and the services we offer.