The story above is fictionalized and anecdotic. But if you told it to the CEO of a Chinese electricity meter manufacturer, he or she would recognize the significance immediately. “Keep your costs as low as possible.” Most of us have heard that sometime, and it is exactly the challenge that Suzhou Galaxy Camphol Technology Co. Ltd.2 is about to take on for electric utility meters. They now can save this 2.48 ¥ on each meter and will save their national utility 155M ¥ annually. I am going to relate their story. This is a story about innovation, integration, and perhaps most importantly here, collaboration.

The “China Effect” on the Cost of Electricity Meters

The Chinese electricity meter market is by far the largest in the world due to China having the biggest population on earth, approximately 1.4 billion people. China has one (quasi-single)3 state-owned utility called State Grid Corporation of China, arguably the biggest state-owned utility in the world. With revenues close to $300B (1.860B ¥), State Grid was ranked as the seventh largest company in the world in Fortune 500 for 2013.4 We estimate that 60 to 65 million electricity meters (Figure 1) were produced in China for the local market in 2013, a number that is going to grow more than 10% annually in the coming years.5

During my many trips to China, I was told several times that more than 200 Chinese companies are in this utility meter business. Is this true, or not? I will leave this for you to verify, but I can easily list more than 30 major companies manufacturing meters for State Grid.

In this competitive environment, the Chinese electricity meter manufacturers struggle daily to provide products with higher performance and even better cost optimization. Here each penny saved definitely means “big business.”

When Solution Rhymes with Innovation

Suzhou Galaxy Camphol Technology Co. Ltd. is no newcomer to the meter business and thoroughly understands the requirements and specifications of State Grid.

In 2009, State Grid released the specifications for electricity meters, moving away from mechanical meters to solid-state meters and setting a standard for the entire country. Galaxy immediately saw an opportunity for success as they had been working with new meter designs in the Beijing region since 2003, a time when most other meter manufacturers’ expertise was only with mechanical technology. Galaxy’s highest priority was to learn about microcontrollers, how to implement them and how to program them.

In 2010 Galaxy introduced a new solid-state electronic meter that was certified by the China Electric Power Institute (CEPRI), a research institute and subsidiary of State Grid.6 The CEPRI is the only body who can approve a meter for the State Grid biddings. Thanks to their outstanding technical skills and armed with that certified meter, Galaxy started promoting their reference design to all the Chinese meter manufacturers. They rapidly became very successful.

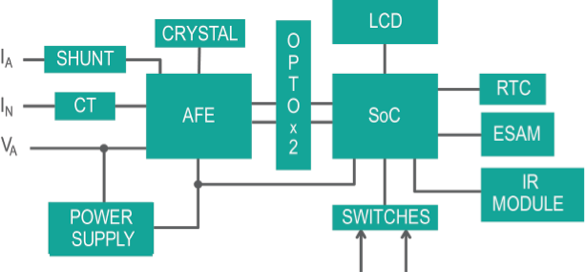

Specifications for electricity meters in China require the meter to isolate the metrology from the data processing. This mandate means that most meters in the country use a similar architecture (Figure 2).

From this typical national design, we return to the 155M ¥ question for Galaxy: how could they reduce the Bill of Materials (BOM) for their device and still comply with the state requirements? I am sure that most of your first answers would point to the microcontroller or the AFE. Not bad, but believe me, considering the high volumes in this market, there is not much that can be done at that level to reduce their price..

Galaxy spoke with Maxim Integrated engineers and we began examining their existing meter architecture. We concluded that the only way to reduce the cost of their electricity meters was to change the architecture of the entire meter. It was time to innovate and integrate.