In addition to saving time, laser technology improves safety and results by utilising miniature optical encoders with high resolution and accuracy to focus exactly on the target spot in surgeries usually done on the human eye, giving it an edge over traditional methods.

Latest applications require improvements in design and manufacture using advanced technologies, especially where size and mass are critical. Developments in robotics and Industry 4.0 have made a significant contribution to the growing possibilities in this market. Laser technology is one such example, where remarkable precision is required to ensure effectiveness.

In the laser-marking process, surfaces of different materials including metals (such as aluminium, copper, gold, silver and platinum), plastics (such as polycarbonate and ABS) and paints get labelled using a low-powered laser beam. Errors in beam or sensor positioning results in damage to products that need to be marked or engraved.

To project a laser beam at the required location while laser-marking items, position of the mirrors is steered using linear motion of voice coil motors. China-based Han’s Laser Group, a global professional laser equipment manufacturer, required a non-contact, compact and highly-accurate optical encoder for controlling velocity and angular position of voice coil motors through feedback.

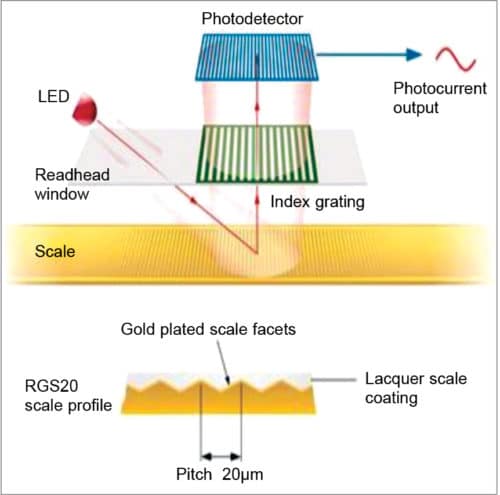

An optical encoder identifies position change as light passes through a patterned encoder wheel or disk. Selecting the right model and knowing the appropriate configuration is crucial for success. There are several encoder manufacturing companies in the market such as Broadcom, Yuheng Optics, Ifm electronic, Siko Gmbh, Allied Motion, Posital Fraba, etc. Among them, one company is Renishaw whose RGH24 incremental encoder system with RGS20 linear scale was chosen as a reliable solution for high dynamic performance. An incremental encoder generates a pulse per step in rotation to determine position and speed, and reports position changes in real time.

Though optical encoders are inherently analogue, RGH24 is a tiny read head (36mm×13.5mm× 14.8mm) that allows both analogue and digital outputs with a capability of integral interpolation up to 10nm for high linear speeds. Sub-divisional error remains as low as ±0.15µm. It has a setup LED that becomes green when installation gets completed accurately and filtering optics for dirt immunity.

RGS20-S tape scale is supplied on a reel for flexibility and can be cut to suit any axis length from 10mm up to 50m and beyond on special orders, ensuring zero waste. Inside the read head, LED emits light onto the angled scale graduations, where it is directed back through a transparent phase grating, producing sinusoidal interference fringes at the detection plane. Signals not matching the scale period are filtered out to maintain signal stability.

The lightweight scale ensures negligible loading on the voice coil motor and can be mounted onto the moving part directly using adhesive backing tape without any extra weight from bolts and clamps. Easy and fast installation ensures a cost-effective assembly. For further stability and lower sub-divisional error, its analogue version can be connected to REE interface, which includes automatic offset control (AOC), automatic gain control (AGC) and automatic balance control (ABC) for efficient operation.

In another instance, a laser-marking systems supplier chose MicroE’s PCB-mounted Mercury 1200 encoder (15.3mm x 12.7mm x 5.6mm) for its servo control system with incremental sine/cosine feedback. Along with space and cost savings, it provides an analogue output that can be interpolated for resolution up to 4.2 million counts per revolution. The encoder weighs only two grams and consumes low power, which helps in maintaining thermal stability of the system. Wide alignment tolerance ensures ease of installation. Besides, it can achieve up to 120nm cyclical error. Coupled with a 12mm diameter optical disk, the encoder provides 200,000 counts per revolution after seven-bit interpolation in client’s electronics, according to azosensors.com.

High precision in movement is important in other similar applications ranging from office equipment such as photocopiers to medical equipment. In addition to saving time, laser technology improves safety and results by utilising miniature optical encoders with high resolution and accuracy to focus exactly on the target spot in surgeries usually done on the human eye, giving it an edge over traditional methods. Care must be taken for protecting them in case of harsh environments. With recent advancements and growing market presence, use of encoders is bound to increase in the future.