Electronics waste can result in serious environmental impact and even contribute to global warming. This is because the materials used to make electronics products are often toxic. This has led to the growth of several organic materials that have semiconductor properties for use in electronics items.

Disposal of electronics waste is a huge problem. When not properly dealt with, electronics waste can result in serious environmental issues and even contribute to global warming. This is because the materials used to make electronics products are often toxic, corrosive, flammable, reactive, infectious, or even radioactive. This has led to the growth of organic materials that have semiconductor properties for use in electronics items. Unlike their inorganic counterparts, these are biodegradable, biocompatible, non-toxic and pose no threats to the environment.

Researches of the past few years have shown that organic semiconductors exhibit promising optical, electrical, and optoelectronic characteristics. Through the addition of different functional groups, these can be made more conducting, photoluminescent, and achieve better efficiency. These non-metallic structures can hence be easily used to manufacture economical, flexible, and green electronics for robust devices of the future, which was not possible with inorganic materials.

The Australian National University (ANU) announced the invention of a part-organic semiconductor by a team of engineers two years ago. This innovation was capable of converting electricity into light very efficiently and was seen as a way of making high-performance electronic devices such as bendable mobile phones. Bending semiconductors made of organic materials can almost double the speed of electricity flowing through them, as proved in a Rutgers University-led study.

Key players in the organic semiconductor market include LG (South Korea), BASF SE (Germany), Bayer AG (Germany), Merck & Co. (US), Samsung (South Korea), Sony Corporation (Japan), and Sumitomo Corporation (Japan). According to a report from Market Research Future, the global organic semiconductor market is expected to grow at a compound annual growth rate (CAGR) of 22.4 per cent, reaching 179.4 billion dollars by 2024.

Organic semiconductors are made up of polymers or π-bonded molecules that are important active materials. These have found numerous useful applications, including organic light-emitting devices (OLEDs), organic lasers, organic thin-film transistors (OTFTs), organic solar cells, bio/chemical sensors, and much more. Among these, OLEDs have seen a huge demand worldwide in recent times as an alternative to existing lighting technologies.

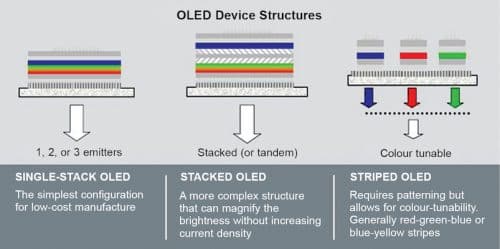

Unlike conventional diodes and LEDs that use layers of n-type and p-type semiconductors, OLEDs employ organic molecules to emit electrons and holes. These consist of semiconducting organic layers stacked between two electrodes. In a basic design, there are six layers of which top and bottom layers are usually made of protective glass. When electrons and holes are injected in the emissive layer, the light gets produced due to the process of electroluminescence.

For better performance, the chosen electrode must have a lower work function compared to the active organic layer when used for injection of electrons and vice versa for hole injection. For high work function, materials like indium tin oxide (ITO) are used while aluminium, calcium, or magnesium are the most common low work function options. Also, a device with large thickness leads to resistance against carrier injection, thereby decreasing carrier mobility and power efficiency. Although the internal quantum efficiency of OLEDs is high, the material of the electrode meant for electron injection must be transparent to visible light for external quantum efficiency.

The main application of OLEDs is as a display in devices like televisions, tablets, and laptops. Panasonic, LG, Sony, and Philips are some of the prominent companies in this field. Active-matrix OLEDs (AMOLEDs), popular in smartphones and tablets, add an extra film of semiconducting material and are more flexible than OLEDs.

Recently launched smartwatch by Nubia sports a large flexible OLED screen that curves halfway round a person’s wrist. Virtual reality (VR) headsets are also now using OLED microdisplays as these provide decreased brightness levels and high refresh rates.

Organic semiconductors are also used in the sustainable production of solar cells. Organic solar cells ensure easy fabrication and offer a low-cost alternative to traditional crystalline silicon-based cells. These are based on the principle of photovoltaic effect. Organic polymers or small molecules present in these cells absorb sunlight and transport charge to produce electricity. These can store large amounts of solar energy due to large surface area and high absorption coefficient.

Research is ongoing to combine new materials while developing organic semiconductors for achieving better efficiency in applications. In August, a team of engineers from the Queensland University of Technology created a semiconductor capable of producing transistors, solar cells, and other electronic circuits by combining organic hydrocarbon naphthalene with a pigment called DPP, which is commonly used in Ferrari paint. Further advancements in the design process and adoption by emerging economies offer a promising future for organic semiconductors.