Over the years, lithium-ion (li-ion) rechargeable batteries have become immensely popular, but their production process incurs large carbon footprints. Hence, there is an urgent need to find alternatives to these batteries.

Batteries are a core technology that power portable electronic devices like smartphones, vehicles, and even provide a backup for the growing renewable energy used in homes, offices and electricity grids by converting chemical energy inside them to electrical energy. In the past few years, lithium-ion (li-ion) rechargeable batteries have become immensely popular due to their high energy density over a wide temperature range and low self-discharge, finding their use even in military and aerospace applications.

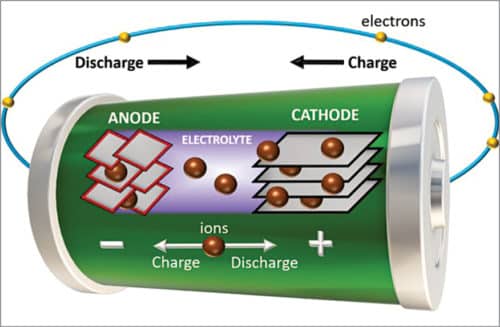

Just like any other battery, li-ion batteries are made up of a combination of cells, with each cell consisting of anode and cathode that are separated by an electrolyte. The cathode is made up of a lithium compound (such as lithium cobalt), and the anode is typically built from graphite. The electrolyte is usually a lithium salt (lithium hexafluorophosphate) in an organic solvent. During discharge, lithium ions move from cathode through the electrolyte to anode and vice versa during charging. The cells need a protective circuit to limit the peak voltage.

Owing to climate change, we need the development of a sustainable and low-carbon value chain for batteries. The storage of energy heavily relies on heavy metals in batteries. The problem with li-ion batteries is that besides being expensive, extraction of raw materials available in underdeveloped nations is often done in unsafe working conditions, and a huge amount of water gets wasted in the process. Sometimes, it even leads to leakage of toxic chemicals into the water cycle. The production process incurs large carbon footprints, and their disposal is a huge problem. Besides, with China being dominant in li-ion battery manufacturing and battery supply chain, the coronavirus pandemic has led to a series of disruptions in the supply chain.

As the basis for future mobility, there needs to be a defined sustainability criterion for battery design as well as focus on reuse and recycling to boost a circular economy, especially in developing and underdeveloped countries. But the cost of recycling li-ion batteries is higher than manufacturing these from scratch. For moving to a more sustainable future, these issues need to be fixed. There is a dire need for implementation of effective coordination and policies among public, private, and civil society organisations for the deployment of sustainable batteries. In this direction, the Global Battery Alliance was founded in 2017 for global public-private partnerships.

Several researches are also going on to find alternatives to li-ion batteries. For example, sulphur has been considered to have great potential in this field. Lithium-sulphur batteries are economical, more environmentally sustainable to produce, and safer to use. The issue is that the electrodes tend to break down during charging since sulphur is a poor conductor of electricity and heat. Apart from this, these batteries degrade faster over time.

In another instance, researchers at Purdue University have created a technique to turn waste polyethylene terephthalate, a recyclable polymer, into battery components. This paves the way for organic batteries. Biomass-derived electrodes (both carbonised and non-carbonised), electrolytes and separators (membrane between cathode and anode) are a growing topic of interest for analysis. Biomass-based binders can replace toxic halogenated commercial binders for holding the active material particles inside electrodes and ensure sustainability.

Numerous companies are adopting these technologies, and the situation is gradually changing. Last year, IBM developed a new type of battery that uses raw materials from seawater and is free of cobalt, nickel and other heavy metals, thereby avoiding the trouble of mining and so reducing costs involved in the process. The battery, which is in an early stage of development currently, has a higher power density besides low flammability as compared to lithium-ion versions.

Sodium-ion is another option that has gained significant attention. Even for lithium-sulphur batteries, it has been observed that the addition of molybdenum makes the electrodes conductive and stable. With further research and collaboration, it is possible to expect fully stabilised alternative materials that can be introduced in the market for real, practical, commercial applications in future.