The proposed off-grid integrated system will be very useful when there is a sudden grid failure. It will continue to provide charging for two- and four-wheelers. Besides it will enable bio-CNG dispensing, sale of milk, sale of organic manure, sale of cow urine for medical usage that can even be exported, and let you claim carbon credits as well.

Many new technologies are getting introduced across the length and breadth of our country, such as:

- EV charging stations

- Compressed biogas plants

- Agri-voltaic farms (coming soon)

- Battery based energy storage systems (coming soon)

- Hydrogen generation systems (coming soon)

As of today, all these systems are being planned in silos and are being built as independent systems. But this is the right time to plan integrated systems, which can offer additional benefits, apart from their intended use. It will allow us to derive multiple benefits. A brief introduction to each of the above listed technologies is given below.

EV charging stations

The number of electric vehicles is increasing day by day, which is also increasing the need for EV charging stations. Both government and private companies have started building charging stations. These stations are of two main categories: within the city and along the highways. Here we shall focus on the charging stations being installed along the highways and major roads between cities.

Almost all of these charging stations are grid-based. Grid-connected systems are easy to install, need less investment, and take up less space. However, they are going to put a huge load on the already overloaded grid. Also, imagine what will happen if there is a grid failure?

Therefore, to tackle such a situation, we should have some off-grid charging stations as well. Such charging stations will reduce load on the grid and will be very beneficial in case of a prolonged grid failure.

There are two- and three-wheeler chargers as well as four-wheeler chargers. The four-wheeler chargers themselves are of three types.

Level 1 (L1) chargers

These are slow chargers that take eight to ten hours to charge a depleted battery. Hence these are used in residences for overnight charging.

Level 2 (L2) chargers

These take about four hours to charge. Such chargers are installed in housing complexes, workplaces, restaurants, malls, etc.

Level 3 (L3) chargers

These are DC superfast chargers. An L3 charger can charge a depleted battery to 80% within an hour or two. These are special chargers that are installed by the automotive manufacturers or government agencies along the highway.

Compressed biogas plants

Biogas plants are quite common. These plants use bio waste material, cow dung, etc, and produce methane gas. This gas is normally used for cooking. However, if we have to use it for CNG vehicles or for generators, the raw biogas has to be treated; it contains carbon-dioxide, water vapour, and hydrogen sulphide gas. When these unwanted gases are removed, we get 90% concentration of methane, which is then compressed. Compressed biogas is a good substitute for CNG.

If biogas is used to generate electricity using standard available bio-gas generators:

- One cow provides 1000kWh (units) of electrical energy per year

- One cow provides 2.75kWh energy per day

- Hundred cows provide 275kWh energy per day

If biogas is used for making bio-CNG:

- One cow provides 1.5 cubic metres of raw biogas per day

- Hundred cows provide 1500 cubic metres of raw biogas per day

- If purified, 100 cows provide 900 cubic metres of pure methane per day

Agri-voltaic farms

Agri-voltaics is a combination of agriculture and solar photovoltaic (PV) energy generation. PV power plants need large stretches of land. Usually, the land selected for PV installations is barren land. In many places fertile land is also being used. If agriculture land has to be used, then agri-voltaics should be preferred.

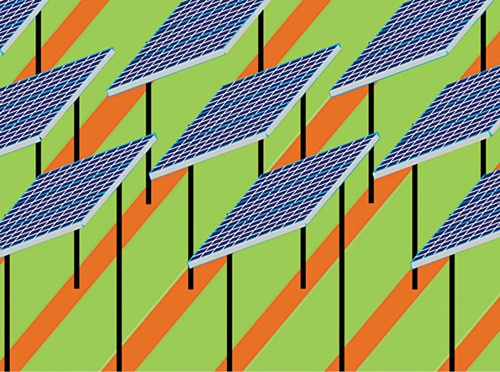

In agri-voltaics, the PV panels are installed at a height of more than 244cm (8 feet). And only 50% area is covered by the panels, as shown in Fig. 1. Fig. 2 shows close up view of an assembly of three panels each.

The gaps between the panels allow the sunlight to fall on the land below, permitting cultivation. In the shade of solar panels, various types of vegetable and flowers can be easily grown. As the land is partially shaded, the plants need less water. In spite of less water usage the yield is the same or sometimes better.

The presence of plants provides cool air to the solar panels. Cooler PV panels produce increased power output. The water used for cleaning the panels irrigates the plants and does not go waste. The farmer is assured of regular income by selling electric power generated by the PV panels. Also, he can do the farming and double his income.

Let us have a look at a PV system design:

- One acre area=43560sq ft

- Area of each 300Wp PV panel =6.5×3.25=21.125sq ft

- Number of 300Wp panels possible=43560/21.125=2062

- Number of panels if only 50% area is covered=1031

- Panels after leaving 13% area for construction=900

- With 3 panels in each PV assembly, number of assemblies=300

- Slots with 20×30 arrangement =600 (adjacent slots left vacant)

- Power output=300Wp×900= 270,000Wp or 270kWp

- Charging power (assuming 90% efficiency of chargers)=270× 0.9=243kWp

- Average charging power available for 8 hrs on a sunny day =200kW

- Maximum number of 25kW charges which could be run=8

- Total energy generated in 8 hours=200kW×8hrs=1600kWh or 1600 units

Battery-based energy storage systems

Electric grid gets power from various sources, such as coal power plants, hydel generators, nuclear, solar, and wind. As a greater number of solar and wind power plants are getting installed, the renewable energy content in the mix is increasing.

Unfortunately, the renewable energy sources are highly variable and unpredictable. This poses problem for the grid stability. Sometimes there is excess power generation and other times there is sudden reduction in generated power.

In order to stabilise the grid, there is need for short-term energy storage. A battery bank can be used in such a situation. When there is excess energy, the batteries can store the energy. When there is demand for energy from the grid, stored energy from the batteries can be used.

Even though use of batteries appears to be a simple solution, the cost of these batteries is very high. Luckily, this being a land based application, size and weight of batteries is not very critical. Hence, even the cheaper lead-acid batteries can be used.

Another option for reducing the cost is to use discarded lithium-ion batteries from electric vehicles. Such batteries still have about 75% storage capacity. These batteries can be used for a few years, as their second life.

Gravity batteries

As the demand for lithium-ion batteries is increasing, the prices of metals like lithium, cobalt, and nickel are shooting up, resulting in increased price of lithium-ion batteries. To overcome this problem, alternatives such as gravity batteries are being tested.

A heavy block of cement is raised using a crane or elevator mechanism. The block acquires potential energy proportional to the height to which it is raised. When power is needed, the block is slowly lowered, which drives the generator. Such batteries are cost-effective and have life span of more than 25 years.

Here is an example of the gravity battery’s capacity:

- Potential energy=[(mass× acceleration due to gravity×height)/ 3600]Wh

- Mass in kg, g=9.81m/sec2, height in metres

- For 100-ton slab, raised to 100m height, energy stored=27.25kWh

Hydrogen generation systems

Hydrogen is emerging as an alternative to fossil fuels. To make green hydrogen, renewable energy is used. When current is passed through an electrolyser, it splits the water molecules into hydrogen and oxygen.

Hydrogen has many uses

We can mix hydrogen with CNG up to 20%. This mixture of gases can be used in the same equipment as the original CNG generator or vehicle, without any modification to the engine. Also, the safety precautions remain the same as for pure CNG handling. Thus, whenever renewable energy is available in excess quantity, it can be stored as hydrogen gas.

The above calculations assume average values of the parameters and are for general guidance only. While designing an actual system more accurate data has to be considered. For example, type of PV panel, the average sunlight conditions for the selected region, breed of the cows, etc will have large impact on the accuracy of calculations.

A word of caution. Green hydrogen is an emerging field, and the gas is highly explosive in nature. There are safety concerns while handling hydrogen. Government has announced National Hydrogen Mission. We need to set up safe operating procedures and should have trained manpower to handle the gas. Till then, it is not advisable to go for hydrogen based systems. It may take a few years to reach maturity stage.

System design

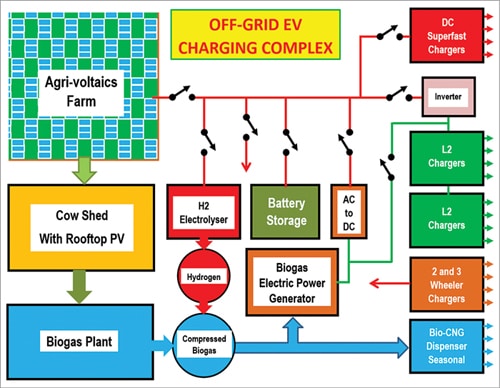

The layout of proposed EV charging complex is shown in Fig. 3. The agri-voltaics farm is central to this system, around which the whole complex is designed. This farm generates DC power in daytime from the sunlight. The PV power is supplied to DC superfast chargers, L2 chargers, and 2- and 3-wheeler chargers.

Standard L2 chargers need AC input. Therefore, an inverter is used to convert DC supply to AC before connecting to L2 chargers. The DC and L2 chargers need a few tens of kW, hence these will work only when sunlight is strong. The 2- and 3-wheeler chargers need much less power, so these will start working as soon as the sun rises.

EV charging as a service provides good return on investment as compared to selling energy to the grid.

Whenever there is excess PV power, it can be stored in the batteries. If the DC voltage drops due to clouds, power from the battery can be used to support the supply.

When the batteries get fully charged, excess PV power can be used for hydrogen generation. The electrolyser splits water into hydrogen and oxygen. The hydrogen can be stored in a storage tank. The simplest way to use this hydrogen is to mix it with CNG. Up to 20% hydrogen can be mixed without needing any modification to the CNG system.

As mentioned earlier, green hydrogen technology is in initial stages of development. Handling hydrogen, due to its explosive nature, is very challenging. We have to wait till this technology matures before using it. Hence, in the initial implementation of proposed EV charging system, we need to find out an alternative to hydrogen electrolyser.

One simple alternative is to have second set of batteries. This can be a chemical battery or a gravity battery. Gravity batteries will have very long life as compared to chemical batteries.

A cow-shed can be established near the farm. As mentioned earlier, the land below the PV panels can be used for farming. In the proposed scheme, the land is used to produce fodder (fresh grass) for the cattle. After meeting fodder requirement, if still there is spare land available, vegetables and fruits can be grown for additional income.

Regular income can be earned by selling cow’s milk. There is also a big demand for cow urine for medical purposes. The cow dung can be used for the biogas plant. The raw biogas generated contains carbon-dioxide and water vapour. Once these two are removed, we get 90% methane, which can be compressed to get bio-CNG.

This compressed bio-CNG can be used for electric power generation during night. The output of this generator is AC, which can be directly fed to the L2 chargers. A rectifier is used to convert AC to DC for the DC superfast charger.

In summer, the PV power generated is more than in winter. Hence, in summer we may have excess bio-CNG in the tanks. Excess bio-CNG can be filled in the vehicles through the CNG dispenser, as shown in

Fig. 3.

The PV panels can be installed on roof-top of the cow shed. This will further increase the PV power generation, providing additional income.

Automation

The proposed system is fairly complex. Therefore, complete automation has to be done for proper operation of the system and to maximise return on investment. Further, all safety systems should be installed for avoiding any untoward incidents.

The solar radiation and weather changes are highly fluctuating. Hence, weather forecasts for next few days should be provided as input to the automation system. Similarly, the pattern of demand for EV charging can be studied and fed as input to the system.

During prolonged spell of rains, the PV power may not be sufficient for meeting the power demands. In that case, for few days, the normal CNG could be used as a backup fuel. Use of artificial intelligence and machine learning program will be very useful for optimal running of the system.

Implementation

The proposed scheme can be implemented in two steps. The first step is to check technical feasibility. A pilot plant can be established and run for 2-3 years to gain insight into the operation of the system. It will generate very useful data.

In the second step, full-scale plant can be built, based on the learnings from the pilot plant. Optimisation can be done based on the data available, in order to reduce the cost of the system.

The cost of implementation will he on the higher side due to the complex nature, but this integrated system will offer multiple benefits. The return on investment will be much higher, which will reduce the payback period.

Some advantages of the system are:

- Off-grid operation reduces burden on grid on daily basis

- Off-grid operation is extremely useful during emergency grid outages

- Shorter cables and less transmission losses

- Carbon-neutral system

- Self-sufficient with minimal movement of material

Some sources of revenue generation are:

- EV charging service

- Bio-CNG dispensing

- Sale of milk

- Sale of organic manure

- Sale of cow urine for medical usage (can even be exported)

- Can claim carbon credits

And some avenues of the savings from the project are:

- Vehicles used for selling milk and manure get free charging or free CNG

- Free electricity for the complex

- Conservation of water because of agri-voltaics

- Extra power generation because of lower operating temperature of panels

- Water used for cleaning the panels goes for irrigation

- Fodder for cattle grown inhouse; less cost and no transportation

- Vehicle owners waiting for EV to charge can visit cow shed and feed the cows

Conclusion

Along the highways there is enough land available for implementing the proposed scheme. An integrated system offers many more advantages. The return on investment is high. Most of the inputs for running the system are available inhouse. Hence there is minimal movement of material.

Except green hydrogen, all other technologies can be easily implemented. The equipment required for the system is available within the country. Thus, a pilot plant can be started with most of the equipment procured locally.

In future, more advanced technologies, such as fuel cells, could be used for more efficient and silent operation. This off-grid system will be very useful when there is a sudden grid failure. It will continue to provide charging for two- and four-wheelers.

Dr Vijay Deshpande currently works for solar energy projects. He has also worked as electronics hardware engineer in several companies