This new method uses ultrasonic waves to separate valuable materials from electrodes.

Over the years, many methods of recycling lithium-ion batteries have evolved. Today, the most common way is to feed the batteries into a high-temperature reactor, where complex processes are used to produce reusable materials. However, these processes involve high energy requirements and are inefficient.

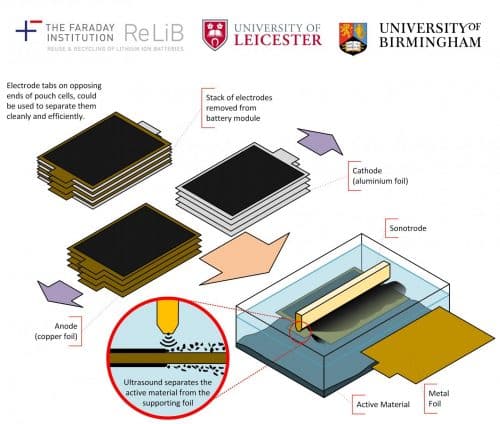

The Faraday Institution project on the recycling of lithium-ion batteries (ReLiB) has come up with a new innovation for recycling vehicle batteries. Led by Professor Andy Abbott at the University of Leicester, the new method uses Ultrasonic waves, to separate out valuable materials from electrodes.

They proposed a rapid and simple method for removing the active materials from composite electrodes using high powered ultrasound in a continuous flow process. The batteries are dismantled rather than shredded which makes it possible to recover more material. Cavitation at the electrode interface enables rapid and selective breaking of the adhesive bond, enabling an electrode to be delaminated in a matter of seconds.

The process has proved to be highly effective in removing graphite and lithium nickel manganese cobalt oxides, commonly known as NMC which enables the full recovery of the materials at the end of the battery’s life.

Professor Andy Abbott also compared the process to a dentist’s ultrasonic descaler, where adhesive bonds between the coating layer and substrate.

“This novel procedure is 100 times quicker and greener than conventional battery recycling techniques and leads to higher purity of recovered materials. It is likely that the initial use of this technology will feed recycled materials straight back into the battery production line. This is a real step-change moment in battery recycling.” said Professor Abbott.

The focus on recycled batteries in today’s fast-growing Electric-Vehicles (EV) industry is a necessity and this technology not only provides a safer and effective alternative to recycling batteries, but also a more environment-friendly approach. Battery manufacturers and recycling companies can utilise this technology in a vision to create sustainable EVs for the near future.