Innovative Protonic Ceramic Electrochemical Cell redesigns now allow operations below 450°C, achieving higher power densities and promising a sustainable energy breakthrough.

Protonic ceramic electrochemical cells (PCECs), with electrolytes based on proton-conducting oxides, offer potential sustainable energy solutions with higher efficiency than traditional cells. Their adoption is limited due to production challenges and high operating temperatures, often exceeding 500°C.

Researchers from Kansas State University, Colorado School of Mines, Nissan Technical Center North America (NTCNA), Nissan Motor Company, and the University of Oklahoma have developed a design strategy to reduce the operating temperatures of PCECs to below 450°C.

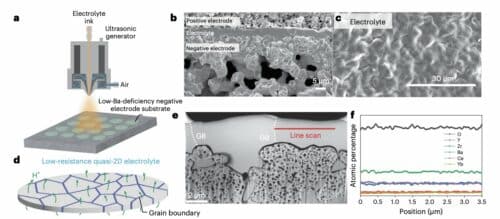

The researchers have developed a composite positive electrode that substantially decreases various resistances in PCECs, such as ohmic resistance and those associated with electrode-electrolyte contact and electrode polarization. Paired with optimal electrolytes, this electrode can notably enhance PCEC performance at temperatures under 450°C. To gauge the efficacy of their design approaches, Liu, Deng, and their team fabricated new PCECs and conducted tests to measure their power densities and operating temperatures in fuel cell and steam electrolyzer modes.

The researchers reported that the PCECs achieved high power densities in fuel-cell mode (~0.75 W cm−2 at 450 °C and ~0.10 W cm−2 at 275 °C) and outstanding current densities in steam electrolysis mode (−1.28 A cm−2 at 1.4 V and 450 °C), with a power density of ~2 W cm−2 at 600 °C. They also demonstrated the direct use of methane and ammonia for power generation below 450 °C and highlighted the stability of their PCECs for power and hydrogen production at 400 °C. These promising initial evaluations indicate the potential of their methods in producing high-performing PCECs for fuel cells and hydrogen support at reduced temperatures. Notably, the electrolyte they developed showcased resistances comparable to or surpassing those in prior PCECs developed through intricate fabrication processes.

The strategies can potentially guide the creation of more PCECs that function at reduced temperatures, paving the way for broader adoption of this nascent energy technology. Moving forward, refinements to the team’s prototype cells could further optimize operating temperatures and enhance performance.