The U.S. Department of Energy’s Argonne National Laboratory researchers successfully adapted a semiconductor coating technique for promising battery materials called argyrodites.

A method traditionally applied in the production of computer chips could significantly extend a battery’s charge capacity and simplify its manufacturing process. Researchers at the U.S. Department of Energy’s Argonne National Laboratory have effectively modified this technique for solid-state batteries, composed entirely of solid materials.

A promising solid-state material, but with challenges

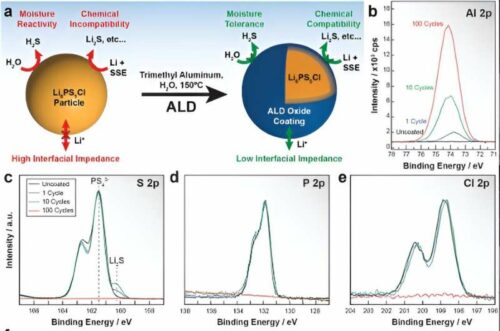

The Laboratory study honed in on argyrodites, a sulphur-containing solid-state electrolyte lauded for their superior ionic conductivity, which allows for swift ion transport, potentially leading to faster charging for electric vehicles, as well as their cost-effectiveness and ease of manufacturing into battery pellets. The researchers sought a method to precisely tailor the chemistry of argyrodite surfaces that could be seamlessly integrated into existing battery production lines. Their solution was to repurpose atomic layer deposition, a technique borrowed from semiconductor manufacturing, where chemical vapours react with a material’s surface to create a protective thin film, mitigating the reactivity challenges of argyrodites.

The coating technique shown to be effective

Researchers have adapted atomic layer deposition for argyrodite electrolytes pre-pellet formation, a novel approach diverging from the traditional post-pellet coating. They uniformly coated electrolyte powder with alumina without altering its structure, a fact confirmed by X-ray absorption spectroscopy. Scanning transmission electron microscopy and energy-dispersive X-ray spectroscopy ensured the coating’s precision, which is critical for optimal electrode interaction. This method markedly reduced the powder’s air sensitivity, easing large-scale production. Coated electrolytes pressed into pellets and tested in battery cells showed enhanced performance, indicating a significant stride in solid-state battery technology and its future industrial application.

Several coating benefits, including an unexpected one

The team’s coating notably reduced the electrolyte’s reactivity with the lithium anode and slowed electron leakage, which is critical as it helps prevent dendrite formation. Surprisingly, the coating also enhanced the electrolyte’s ionic conductivity twofold. These improvements could significantly prolong a solid-state battery’s lifespan by optimising the electrolyte-anode contact, like a water droplet spreading on clean glass.

Reference: Zachary D. Hood et al, Multifunctional Coatings on Sulfide‐Based Solid Electrolyte Powders with Enhanced Processability, Stability, and Performance for Solid‐State Batteries, Advanced Materials (2023). DOI: 10.1002/adma.202300673