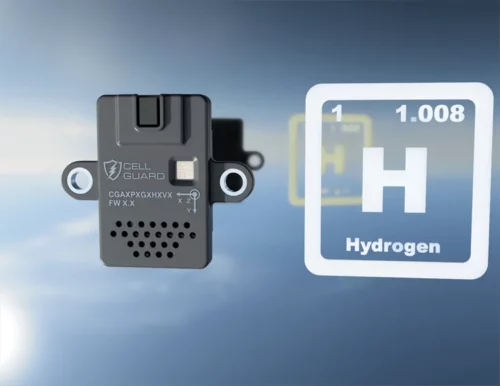

Metis Engineering has introduced an advanced hydrogen leak detection sensor, designed to improve safety in hydrogen energy storage systems and battery packs.

Metis Engineering’s new sensor, Cell Guard with Hydrogen, is specifically built to identify such leaks, offering enhanced safety in industries that rely on hydrogen, including transport, marine, aviation, and industrial sectors as hydrogen is highly flammable, with a wide explosive range, making it particularly dangerous when leaks go undetected. Given hydrogen’s invisible and odorless nature, early detection is essential for preventing fires or explosions..

The recently launched sensor significantly advances the original Cell Guard design. Its primary function is to ensure reliable detection of hydrogen leaks, meeting the most stringent safety standards. The sensor’s accuracy in identifying even minimal hydrogen traces is crucial for preventing risks in hydrogen storage systems. The sensor is particularly relevant for manufacturers and operators of hydrogen fuel cells, energy storage facilities, and industrial users who require stringent safety monitoring.

In addition to its hydrogen detection capabilities, the sensor is designed to monitor fuel cells and battery packs for electrolysis. Electrolysis can occur when moisture enters the system, leading to the production of hazardous gasses like hydrogen. The advanced hydrogen sensor offers early detection, mitigating potential dangers before they escalate.

The Cell Guard with Hydrogen also performs well in high-VOC (volatile organic compound) environments, a common issue in energy storage systems where adhesives are heavily used. These VOCs can complicate detection efforts, but the sensor’s advanced design ensures it can still identify hydrogen leaks, even under these challenging conditions.

The sensor is equipped for use in extreme temperatures, with an operational range between -40°C to +85°C, making it suitable for diverse and demanding environments. Its ultra-low power consumption, operating at less than 1mA, ensures efficient and continuous monitoring without draining energy. In case of a hydrogen leak, the sensor automatically activates the CAN interface for immediate alerts.

One of its standout features is its ability to provide instantaneous hydrogen measurements from startup, eliminating the need for a warm-up period. This real-time monitoring is critical for ensuring safety as soon as the system is powered on.

According to Joe Holdsworth, CEO, Metis Engineering, “We’re excited to introduce this advanced sensor, addressing critical safety concerns in hydrogen storage and battery management systems.”