The team aimed to improve large-area uniformity by replacing screen-printed silver electrodes with high-quality and cost-effective plated copper electrodes.

Solar technology continues to make strides in the fight against climate change, with researchers unveiling a development in the form of silicon heterojunction (SHJ) solar cells. These cells have the potential to revolutionize photovoltaic applications and significantly reduce carbon emissions.

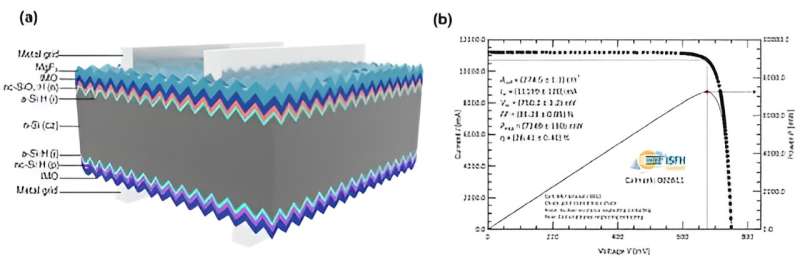

A team of researchers from Suzhou Maxwell Technologies Co. Ltd., Soochow University, New South Wales University, and Dalian University of Technology has recently introduced an approach to SHJ solar cell fabrication. Their findings demonstrate the achievement of power-conversion efficiencies reaching an impressive 26.4%. SHJ solar cells possess several advantages, such as high power conversion efficiencies, cost-effective processing, and low-temperature coefficients. However, their large-scale deployment has been hampered by expensive and non-scalable fabrication processes. These limitations have hindered their commercial success.

The team mentions that the commercial success of high-efficiency SHJ technology remains impeded by challenges in the cost-effective translation to a production environment of several process steps, especially for a high transparent window-layer deposition and low-cost metallisation. They explored alternatives to traditional fabrication methods to address these challenges. They replaced conventional doped a-Si:H with doped hydrogenated nanocrystalline silicon (nc-Si:H) and its alloys with oxygen (nc-SiOx:H) and carbon (nc-SiC:H) to reduce parasitic absorption and series resistance.

VHF PECVD Systems and Plated Copper Electrodes

One key innovation in their approach was using very high-frequency (VHF) plasma-enhanced chemical vapor deposition (PECVD) systems instead of standard radiofrequency systems. VHF PECVD systems offer faster deposition rates and reduced ion bombardment, promoting superior performance. Nevertheless, using VHF PECVD systems presented its own set of challenges, including the need for smaller reactor chambers to maintain uniformity in deposited films. The second major hurdle involved the high-cost metallization process for SHJ solar cells, primarily using low-temperature silver paste. The use of seed-free plated-copper electrodes, as opposed to conventional screen-printed silver electrodes, significantly improved current density and fill factor, ultimately leading to a world-record power conversion efficiency of 26.41% for full-size c-Si solar cells.

These breakthroughs hold the promise of scalable, affordable, and efficient SHJ solar cells that can contribute significantly to reducing carbon emissions and mitigating climate change. As deposition techniques are compatible with existing industrial processes, this research opens the door for further innovation in the field of photovoltaic technologies. Professor Yang emphasized the need for further research and optimization, particularly in understanding the impact of PECVD excitation frequency on film microstructure and device stability. Additionally, the copper plating system for mass production requires further refinement to simplify the process and enhance yield. The development of these high-efficiency SHJ solar cells marks a significant step forward in the transition to sustainable energy sources and brings us closer to a greener future.