Lawrence Livermore Lab develops a silicone-based 3D-printed solutions for electrostatic discharge protection for electronic components.

Research team from Lawrence Livermore National Laboratory (LLNL), California have engineered an innovative electrostatic discharge (ESD) protection solution through 3D printing, aiming to safeguard delicate electronic components from static damage. By using a technique called direct ink writing (DIW), the team has created silicone-based foams that shield electronics from harmful voltage discharges, helping to reduce potential component failures, financial losses, and workplace risks. This development could be a game-changer for industries where ESD protection is critical, such as chemical and electronics manufacturing.

3D printing is a versatile manufacturing method that allows precise control over the printed material’s structure, making it ideal for applications that demand customised mechanical properties. The research team’s process specifically enables the creation of cellular foams with intricate pore architectures that were designed to absorb and evenly distribute stress across a component. This resilience is essential for preventing deformation and mechanical damage, especially when sensitive circuit boards and electronic components are subject to sudden impacts or stresses. Potential adopters include manufacturers in electronics, robotics, and medical device fields where equipment often encounters static and mechanical risks.

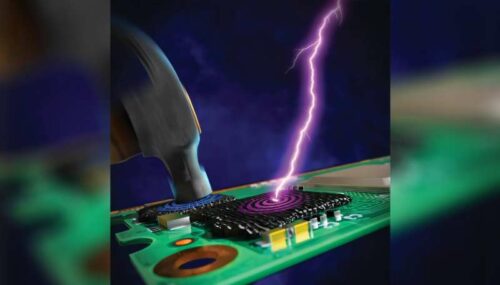

Key to this innovation is the team’s use of direct ink writing (DIW), a specialised 3D-printing technique that extrudes a paste layer-by-layer to build three-dimensional forms. By leveraging DIW, the LLNL team could print a unique silicone resin formulation that includes carbon nanotube (CNT) concentrates and rheological modifiers. These additives allow the structure to achieve the necessary conductivity for ESD protection while maintaining the elasticity and durability needed to withstand impacts, such as those demonstrated by striking the printed structure with a hammer. The CNTs within the resin act as conductive pathways to dissipate static electricity, while the rheological modifiers help achieve the desired print quality and structural precision.

Silicone resins are highly suited for ESD applications due to their low volatility, thermal stability, and elasticity, all of which make them ideal for wearable tech, soft robotics, and other advanced engineering fields. The research team’s 3D-printed silicone shield is applied directly onto circuit boards, acting not only as a static guard but also as a cushioning layer that protects against physical damage. This dual-purpose protection has promising applications for electronics in specialised equipment used in robotics, medical devices and more.

While further refinements are anticipated, the current formulation effectively meets ESD protection needs. With continued advancements, this technology may pave the way for new protective solutions in electronics, enabling safer and more resilient components for industry applications