This process, developed by Prof. Dr.-Ing. Michael Kokes, is particularly effective for fast chargers requiring high power, such as those needed for charging trucks or buses.

Researchers at Heilbronn University of Applied Sciences have developed a system, the 3-phase direct resonant charging system, for automated and thus economical production of quick-charging devices designed for high power.

High-power quick-charge stations are essential for trucks to enable rapid charging. Traditional manufacturing methods for these stations, especially those with power ratings above 100 KW, involve costly line-side transformers or power converters with a DC link and converter, mainly due to the expensive winding materials and capacitors needed.

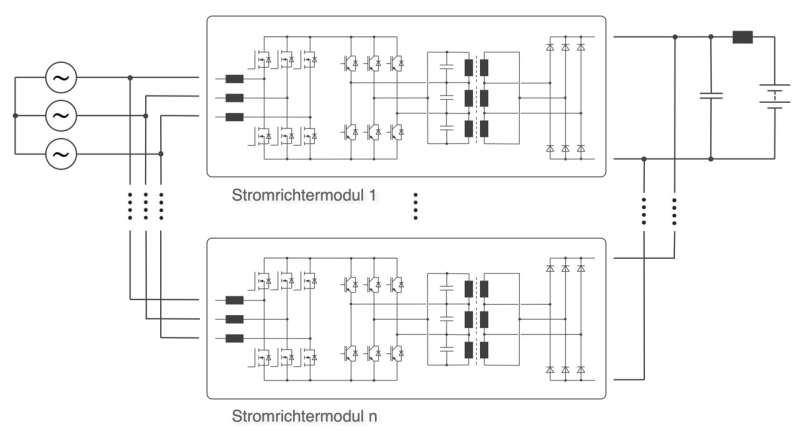

Prof. Kokes’ innovative switching concept utilizes a converter circuit without a line-side transformer and a method to generate a potential-isolated DC voltage, significantly reducing the need for capacitors. This advancement makes the production of charging devices up to several hundred KW far more cost-effective.

Due to the resonant converter’s switching operations for potential isolation, there are no switching losses in the de-energized phases of the DC link. The output voltage is regulated by the line-side converter, and frequency multiplications in the input and output circuits drastically diminish the need for filtering, further cutting costs.

Also, this switching concept allows for a modular design, facilitating automated manufacturing and offering a wide array of combination possibilities. The individual modules can cater to a diverse range of services and models.

This method is particularly well-suited for quick-charging stations for large vehicles like trucks and buses. It also holds promise for automobile charging stations that require rapid power delivery, offering a more cost-effective manufacturing solution.