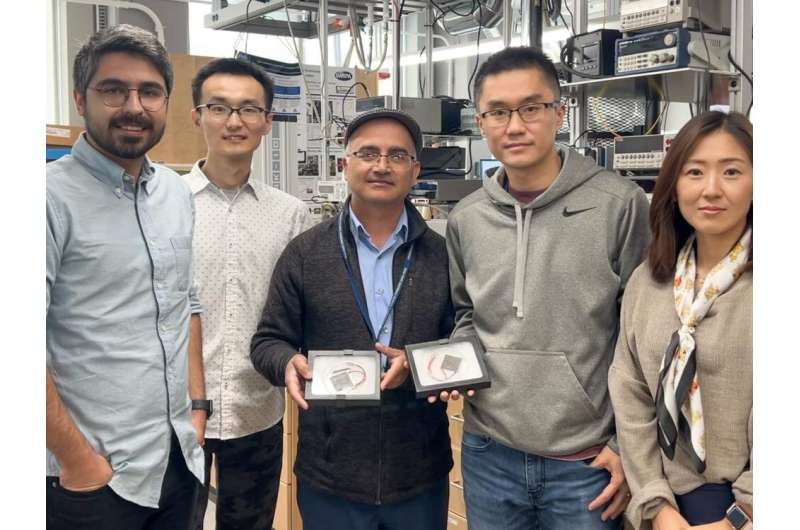

Scientists at Penn State and the National Renewable Energy Laboratory have developed a unique materials design that can push up thermoelectric conversion efficiency.

The usage of fossil fuels is widespread and varied. Many sectors of society, such as transportation, manufacturing, and others, depend on fossil fuels. As a method to diminish the dependence on fossil fuels, one approach is to extract the waste heat that energy systems are already producing.

Scientists at Penn State and the National Renewable Energy Laboratory have developed a unique materials design that can push the conversion efficiency of thermoelectric devices up to 15%. This is the most efficient output recorded to date utilizing this specific thermoelectric technology.

The team has developed a new method for creating functionally graded materials in thermoelectric devices with an efficiency of 15.2% in a single-leg device with a temperature variation of 670 Kelvin. This surpasses the commercially available devices offering 5% to 6% efficiency. The researchers stated that by improving the efficiency of thermoelectric devices, one could move towards greener technologies, which is vital due to the environmental concerns related to global greenhouse gas emissions. Typical thermoelectric generators have segmented designs to enhance performance on different temperature sides, necessitating different material types produced individually and joined by brazing or soldering. The researchers state that this results in a non-uniform interface, lowering device efficiency.

The new method combines the materials for both the higher- and lower-temperature sides, eliminating the need for the interface. The team utilized electrical and mechanical field-assisted sintering to produce the materials. This technique uses current and pressure to solidify powders into a mass, enabling the creation of functionally graded materials by layering powders and adding dopants to tailor the properties. The researchers optimized the chemical compositions of the higher- and lower-temperature sides by using similar materials from the same family that can be sintered at the same temperature in a single step.

Thermoelectric devices have two legs, one of p-type and one of n-type semiconductor material. The study focused on the p-type material, but applying this to the n-type could increase efficiency further. The researchers believe further efforts will optimize temperature ranges by adding layers to the leg, using the one-step sintering technique, potentially improving efficiency.

Reference : Wenjie Li et al, Toward High Conversion Efficiency of Thermoelectric Modules through Synergistical Optimization of Layered Materials, Advanced Materials (2023). DOI: 10.1002/adma.202210407