Harwin releases four spring contact variations, catering to growing multi-directional needs, enhancing printed circuit board (PCB) design flexibility and reliability.

Harwin unveils four additional height variations for its versatile spring contact range, extending from 4.00mm to 10.00mm. While numerous spring contacts are apt for vertical compression uses, it’s rarer to encounter ones supporting horizontal functions. The allure of multi-directional capability arises as the demand for more compact electronic layouts grows, offering engineers increased adaptability in linking PCBs.

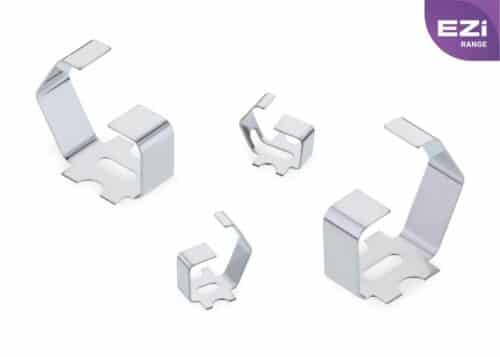

The smaller S1921-46R and S1931-46R models have free heights of 4.00mm and 5.50mm, respectively. In contrast, the higher S1981-46R measures 8.50mm, and the S1991-46R stands at 10.00mm. A significant distinction of these contacts lies in their height. These spring contacts reach the pinnacle regarding vertical dimensions. They can extend up to a free height of 10.00mm, and when factoring in their position over a PCB, they maintain a working height of 9.50mm. This vertical stature provides engineers with an expanded realm of opportunities, allowing for more versatile vertical compression configurations in PCB layouts.

Current ratings of up to 14 Amps enable the spring contacts to be used in low-level power delivery applications, signal transfer, and enclosure grounding tasks. They are typically used in communications equipment, consumer electronics, industrial control and monitoring systems, instrumentation, retail tracking devices and kiosks.

The company crafts its spring contacts using a robust copper alloy. This material choice endows the contacts with exceptional spring characteristics, maintaining their resilience even after prolonged use, boasting a mating durability exceeding 5,000 cycles. A standout feature of these spring contacts is their multi-directional design, which ensures a consistent and dependable connection with the mating surface in horizontal or vertical orientations. They exhibit a high tolerance for wiping and sliding actions, underlining their robustness and versatility.

“Our multi-directional spring contacts provide a much more flexible method for connecting PCBs to accommodate different arrangements, Since their initial introduction, we received many customer requests to develop more compact spring contacts with smaller footprints, lower profiles, and taller options. This means our customers can meet a broader spectrum of application criteria,” explains Ryan Smart, vice president of products at Harwin.

Harwin’s spring contacts are provided in a tape-and-reel format, optimising them for automated PCB assembly. By bypassing manual assembly, this selection of SMT products emerges as a compelling and economical choice for projects of any scale.