MIT researchers have integrated fibre-based fabrication and magnetic programming to develop locomotive magnetic soft robots.

Magnetically controlled soft robots are flexible robotic systems utilising magnetic fields to manipulate shape and movement. Challenges in developing magnetically controlled soft robots include magnetic actuation design, power supply, integration, safety, etc.

Researchers at MIT have combined fibre-based fabrication systems with mechanical and magnetic programming methods to create magnetic soft robots capable of locomotion under unidirectional magnetic fields. The researchers address challenges in creating magnetically controlled soft robots, enabling 3D structures with enhanced functionality, and overcoming scaling, production, and deployment issues faced by previous teams.

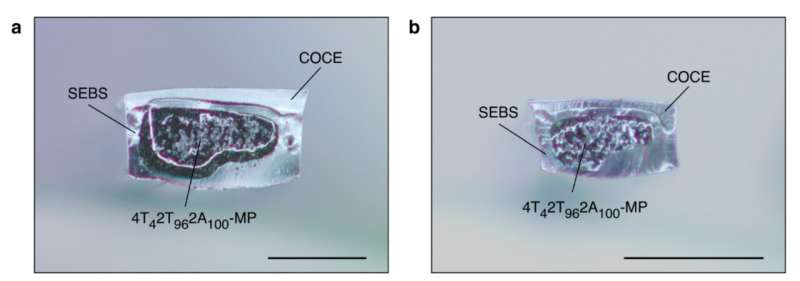

The bulkiness of the required equipment presents a significant obstacle in utilising magnets for controlling soft robots. The team employed fibre-based actuators and magnetic elastomer composites to address this issue. Additionally, they tackled the production challenge by fabricating the actuators through thermal drawing, enabling the development of a flexible ferromagnetic material. Subsequently, every structure underwent a strain regimen inducing them to adopt a helical configuration. This specific arrangement facilitated foldability at various points, enabling constriction and relaxation reminiscent of the movement of caterpillars. The incorporation of additional folding points enhanced the overall flexibility. To emulate bipedal motion, specific folding points were introduced to transform segmented structures into linear leg and foot shapes.

The resulting 3D robots demonstrated the ability to be controlled by varying the strain applied to a given robot and adjusting the strength of a magnetic field. As a result, worm-like robots were created, with some capable of crawling while others could walk. The researchers have highlighted that locomotion was achieved by employing a magnetic field perpendicular to the motion plane as a key factor. Additionally, the robots have been programmed to carry cargo or perform synchronised actions with other similar robots, showcasing their potential for cooperative tasks.

The team have emphasised the robot design’s scalability, opening up possibilities for utilising magnetically controlled soft robots in various biomedical and engineering applications.

Reference: Youngbin Lee et al, Magnetically Actuated Fiber‐Based Soft Robots, Advanced Materials (2023). DOI: 10.1002/adma.202301916