Innovative research develops low-temperature flexible electronics making durable and adaptable next-generation devices.

An advancement in flexible electronics has been achieved at Daegu Gyeongbuk Institute of Science and Technology (DGIST), South Korea. The research was led by Kwon Hyuk-joon and Dr. Jang Bong-ho, professor, DGIST has devised a novel method to fabricate thin-film transistors (TFTs) at significantly reduced temperatures by using self-generated combustion heat.

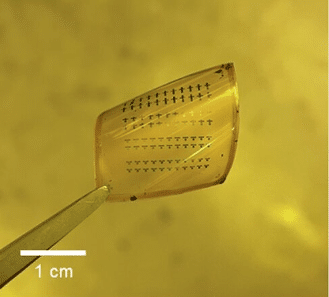

This research addresses a key challenge in flexible electronics manufacturing which is the need for high temperatures to produce high-performance components. Traditional processes often exceed the thermal tolerance of plastic substrates, limiting their application in bendable and wearable devices. However, the new approach, called combustion synthesis, allows the formation of high-quality oxide films at temperatures as low as 250°C, developing compatibility with heat-sensitive materials.

The innovation holds particular significance for industries focusing on wearable technology, healthcare monitoring, and smart consumer gadgets. Developers of devices like fitness trackers, foldable smartphones, and medical sensors stand to benefit greatly from these advancements. The technology’s ability to produce durable, flexible electronics expands design possibilities while maintaining cost-effective production methods.

The innovative combustion synthesis process sidesteps these limitations by generating heat internally within the materials during the liquid-phase process. This mechanism mirrors the way heat packs generate warmth without external energy sources. The result is high-performance thin films on plastic substrates, which maintain electrical efficiency even after extensive bending tests by surpassing 5000 cycles without degradation.

“Conventional liquid-phase materials offer excellent compatibility with printing technologies but require high temperatures to achieve quality thin films,” explained prof. Kwon. “Our findings significantly reduce this barrier for their use in flexible substrates.”

By creating more versatile, high-performance designs, this research marks a significant step toward transforming wearable technology and consumer electronics into everyday tools. Prof. Kwon emphasised that the research results “dramatically expand the potential for flexible electronics by lowering process temperatures.”

Modern lifestyles increasingly rely on flexible and wearable electronic devices, such as smartwatches and foldable screens, for convenience and adaptability. To meet these demands, highly precise and robust electronic components are essential. While liquid-phase processes are ideal for cost-effective mass production, their reliance on elevated temperatures has hindered their use in flexible designs.