By eliminating the need for water and reducing energy consumption, this promises to lower battery costs and significantly reduce their CO2 footprint.

Typically, EV batteries use lithium nickel manganese cobalt oxide (NMC) in the cathode, with elements mixed in its crystal structure. The conventional process involves dissolving these elements in water, forming crystals when they solidify. This method demands a large amount of water—which requires subsequent treatment—and considerable energy, driving up costs and the carbon footprint Switching from gas-powered cars to electric vehicles is crucial for reducing carbon emissions. However, the manufacturing of lithium-ion batteries for EVs is energy-intensive and polluting.

Researchers at Dalhousie University have now developed a greener and more cost-effective manufacturing process. The researchers mentioned that making lithium-ion cathode material consumes a lot of energy and water, producing significant waste. This has a considerable environmental impact, especially on the CO2 footprint of the battery, they sought environmentally friendly, sustainable, and less expensive methods to produce these materials. Using the Canadian Light Source (CLS) at the University of Saskatchewan, the team explored an all-dry process to achieve the same results while conserving energy, water, and costs. They aimed to see if combining dry materials with simple, large-scale factory processes and heating them could produce commercial-grade material without water and waste.

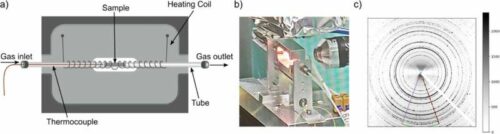

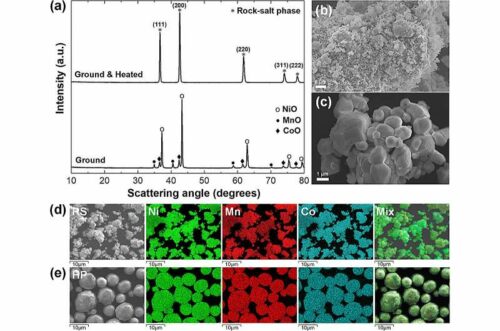

Homogeneity is a challenge with cathodes made from dry materials compared to those made in water. The team experimented with various methods, using different oxides and heating conditions to find the optimal approach. They utilized the Brockhouse beamline at CLS to observe the internal furnace processes during these experiments. This helped them identify ways to improve the dry process, yielding high-grade NMC-type cathode materials. The highest quality cathodes today are made from single crystals about 5 microns in diameter. By adjusting starting materials and furnace conditions,the team successfully replicated these qualities using an all-dry process.

They partnered with NOVONIX, a Nova Scotia-based battery company, to produce cathode materials at a pilot-scale facility in Dartmouth. This facility can produce 10 tonnes of cathode material annually, with an estimated 30% lower capital costs, 50% lower operating costs, 25% less energy use, no process water requirement, and zero waste. This is a significant advancement in battery material production and promises lower-cost batteries with a substantially reduced global warming footprint.