Researchers at Los Alamos National Laboratory have created grooved electrodes for PEMFCs with multiple microscale ridges, improving performance and durability.

Proton-exchange membrane fuel cells (PEMFCs) offer a compelling energy solution to curb carbon emissions in the transportation industry. These cells incorporate a polymer-based proton-conducting membrane that acts as an electrolyte. However, for PEMFCs to be widely adopted, enhancements in their cost, durability, and the accessibility of the necessary fuel are necessary.

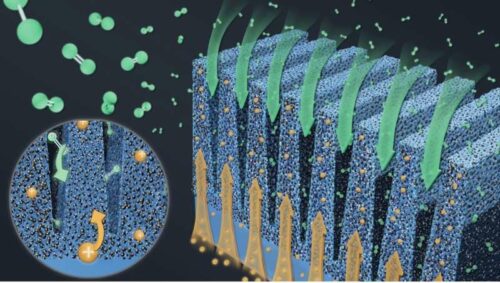

Los Alamos National Laboratory researchers have developed new grooved electrodes for PEMFCs, enhancing performance and durability. The team designed grooved electrodes featuring multiple microscale ridges. These ridges comprise a carbon-supported platinum catalyst interspersed with empty indentations. The distinctive design of these electrodes enables the segregation of oxygen and proton transport within distinct regions of their structure.

In a series of tests conducted under standard operating conditions for fuel cells, the researchers assessed the performance of their grooved electrodes. The results revealed that these electrodes exhibited a remarkable improvement of up to 50% compared to conventional electrodes. Notably, the grooved electrodes enhanced oxygen transport and contributed to more uniform chemical reactions. Furthermore, they exhibited greater durability than traditional electrodes, as their performance degradation after a carbon corrosion test was comparatively minimal.

The preliminary findings of the research team are extremely promising, indicating that the implementation of grooved electrodes has the potential to enhance the performance and durability of PEMFCs greatly. Additionally, reducing the size and production expenses associated with these fuel cells is possible. It is important to note that while their recent work serves as a proof of concept, using microfabrication techniques to construct the prototypes would present challenges when attempting to implement this approach on a larger scale.

Further work on roll-to-roll production of the grooved electrode structure is required to transition this concept from the laboratory setting to actual manufacturing. Simultaneously, the researchers are exploring alternative approaches to rational electrode design, aiming to create new electrode architectures that surpass the performance and durability achieved by the grooved electrode.

Reference: ChungHyuk Lee et al, Grooved electrodes for high-power-density fuel cells, Nature Energy (2023). DOI: 10.1038/s41560-023-01263-2