Energy-efficient motors and scalable technology for industrial applications. Dive into the future of robotics and SOM best practices.

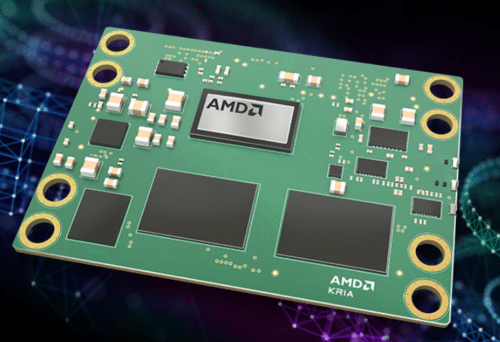

On October 10th, 2023, AMD specialists virtually launched the Kria K24 System on Module (SOM). Key presenters included Chetan Khona, Senior Director; Giulio Corradi, Fellow for Industrial, Vision, Healthcare & Sciences; and Karan Kantharia, Product Marketing Manager for Kria SOM. Corradi showcased the new SOM’s features, noting its impressive compactness – nearly half the size of a credit card. It’s tailored for size, power, and cost-sensitive industrial edge applications, including electric motor control and those demanding robust digital signal processing. The KD240 starter kit was also presented to complement the Kria K24 SOM in drive development.

High-performance DSP is vital for managing modern motor systems using Silicon Carbide and Gallium Nitride electronics, leading to potential global electricity savings. ECC-protected memory and hardware root of trust are crucial for reliable systems. The given SOM portfolio offers scalability, ensuring connector compatibility between the previous SOMs.

Khona remarked, “Electric motors use 70% of industrial energy globally. New materials and designs improve efficiency. Enhanced efficiency can greatly reduce global electricity use. The onset of the Industrial IoT edge comes with digitising analog sensor data. Fast data processing is crucial for real-time control and analytics. The new SOM provides developers an energy-efficient DSP with high computational power, ideal for applications needing quick and reliable performance.”

Faster, Energy-Efficient, and Adaptable Solutions

Using the SOM, craft highly efficient digital signal processing (DSP) solutions that prioritise energy conservation and strongly focus on reliability. They claimed their solutions boast a latency edge, twice as fast as traditional systems like Texas Instruments AM64xx, particularly for single-axis drive applications. Systems that are not only scalable but also adaptable, thanks to their comprehensive compatibility with a broad spectrum of sensors and peripherals, are introduced. Harness the power of pre-integrated Vitis motor control libraries for hardware acceleration. Furthermore, developers can explore multiple development pathways, including tools like Python and the MATLAB Simulink platform. The platform ensures smooth signal processing, paving the way for expedited development.

The key specifications include:

- A53 Quad core

- Supports Ubuntu OS 22.04 version

- 132 I/O ports for versatile connections to motors, sensors, and connectors

- Comprehensive system features for mixed-criticality, functional safety, cybersecurity, and HMI

- Compatibility with various environmental orientation and vision sensors

- Real-time deterministic networking

For embedded developers, there are several key application areas to target. In robotics, there’s a focus on joint control, actuation, and motion. Power generation emphasises the control of pitch and yaw. Communication is pivotal in multi-level inverter systems. Additionally, in electric vehicle (EV) charging, there’s an emphasis on inverter control and Vehicle to Grid (V2G) communication.

New Starter Kit for Robotics

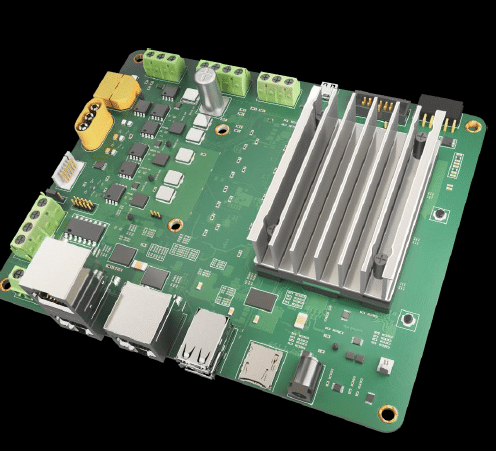

A comprehensive solution for embedded software developers with the Kria KD240 Drives Starter Kit is now available. This kit promises cost-effective solutions and faster deployment timelines, making it readily accessible to the design communities. Critical applications for the system encompass a range of controls. These include customising field-oriented control, harnessing position sensor-based control mechanisms, utilising sensorless control, and effectively coordinating motion.

Coupled with the motor accessory pack, Kria App Store, and support for both Python and MATLAB/Simulink flows, this kit empowers developers. They can engage a motor out of the box with field-oriented control loops. Following this, they can swiftly progress to tuning the pre-existing algorithms according to their specific requirements for multiple independent control axes.

SOM Selection, Development, and Deployment Best Practices

The webinar also highlighted how using a System on Module (SOM) for development and deployment is increasingly becoming the norm. When choosing a SOM, it’s crucial to review its specifications, ensure it meets the requirements, and consider system-level design. For the development phase with a SOM, assess its capabilities using an off-the-shelf kit and then tailor the design for the specific end application. As for deployment, one should craft a carrier card tailored to a custom form factor, modify it to fit specific needs, and then seamlessly integrate it into the end system for production rollout.