Lithium metal batteries, which could significantly increase the driving range of electric vehicles, have their cycle life extended by simply resting them in a discharged state for several hours, providing an easy solution to their rapid degradation issue.

Electric vehicles (EVs) of the future may travel 500 to 700 miles on a single charge, thanks to lithium metal batteries, potentially doubling the range of today’s EVs powered by conventional lithium-ion batteries. However, lithium metal technology faces a significant hurdle: the batteries quickly lose their energy storage capacity after just a few charge-discharge cycles, making them impractical for long-term use in EVs.

Researchers from Stanford University have introduced a cost-effective method to extend the lifecycle of lithium metal batteries. The simple solution involves draining the battery and allowing it to rest for several hours in its discharged state. This approach has been shown to restore battery capacity and enhance performance, offering a straightforward way to improve the technology’s viability for electric vehicles. Wenbo Zhang, a PhD student in materials science and engineering at Stanford and co-lead author of the study, emphasized the pursuit of an accessible, inexpensive, and rapid enhancement for the cycling life of lithium metal batteries. By resting the batteries in a discharged state, capacity loss can be reversed, and cycle life can be prolonged without additional investment in equipment, materials, or changes in the production process.

This finding could significantly impact EV manufacturers by providing a practical solution to leverage lithium metal technology under real-world conditions. Yi Cui, a professor at Stanford and senior author of the study, highlighted the importance of this research in guiding the development of lithium metal batteries toward commercial success.Lithium metal batteries, which replace the traditional graphite anode with electroplated lithium metal, can store twice as much energy in the same space as lithium-ion batteries and are lighter, enhancing EV performance. Despite their advantages, these batteries degrade swiftly due to the formation of “dead” lithium during charge-discharge cycles.

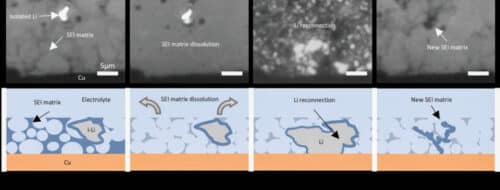

The team’s discovery that resting a fully discharged battery can dissolve parts of the solid electrolyte interphase (SEI) matrix, which traps dead lithium, allows for the reintegration of this lithium into the anode upon recharging, thereby reviving the battery’s capacity. The simplicity of this solution, which involves no new manufacturing techniques or materials, offers a promising path forward. It suggests that with adjustments to the battery management system software, the cycle life of lithium metal batteries in EVs could be significantly extended, addressing one of the key challenges in adopting this technology for electric transportation.