This space-saving device is designed with a BWL structure and a high ID rating of up to 795 A, allowing it to handle more power in a smaller space. Its low thermal resistance (RthJC) of 0.21 °C/W helps it stay cooler and perform better.

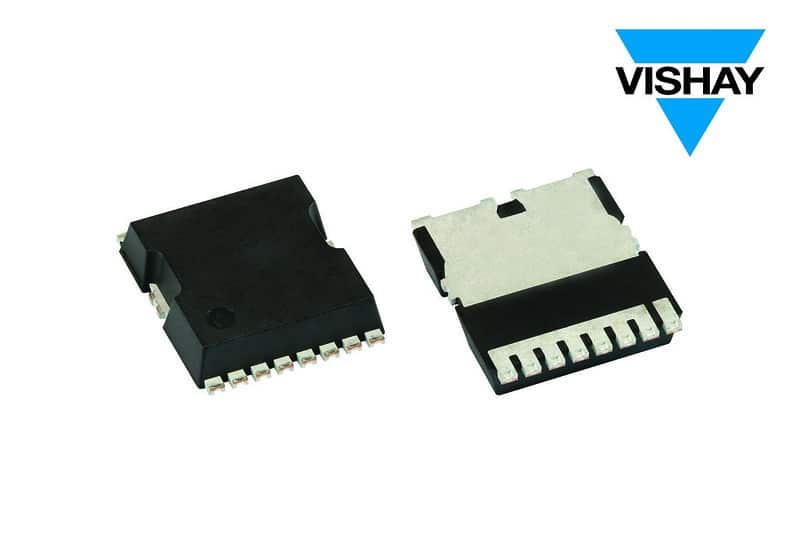

Vishay Intertechnology, Inc.has launched the SiJK140E, a revolutionary 40 V TrenchFET Gen V n-channel power MOSFET designed to elevate efficiency and power density in industrial applications. Housed in the PowerPAK 10×12 package, this device sets a new standard with its best-in-class on-resistance and space-saving design.

Compared to competing solutions, it reduces on-resistance by 32% within the same footprint and achieves 58% lower on-resistance compared to 40 V MOSFETs in the TO-263-7L package. With an impressive typical on-resistance of 0.34 mΩ at 10 V, it minimizes conduction power losses and enhances thermal performance, boasting a low thermal resistance (RthJC) of 0.21 °C/W. This optimization allows designers to replace two parallel devices with a single SiJK140E, improving reliability and extending the mean time between failures (MTBF).

The key features include:

- Compact Size: Occupies just 120 mm², saving 27% PCB space.

- Slim Profile: Features a 50% lower profile for streamlined designs.

- High Performance: Delivers robust Safe Operating Area (SOA) performance.

Featuring a bond-wireless (BWL) design, the SiJK140E significantly reduces parasitic inductance. It supports a continuous drain current of up to 795 A—far exceeding the 200 A limit of traditional bond-wired packages like TO-263-7L. The SiJK140E is tailored for synchronous rectification, hot-swap switching, and OR-ing functionality applications. It is an ideal choice for motor drives, power tools, welding equipment, plasma cutters, battery management systems, robotics, and 3D printers. The device features a high threshold voltage of 2.4 Vgs to prevent shoot-through. RoHS-compliant and halogen-free, it undergoes rigorous Rg and UIS testing to ensure quality and reliability.

Samples and production quantities are available now, with lead times of 36 weeks. It promises unparalleled performance, compactness, and efficiency for modern industrial needs.