University of Massachusetts and Pennsylvania researchers develop a novel alloy for energy conversion applications.

A research team from the University of Massachusetts and Pennsylvania has synthesised a multiscale multi-principal element alloy (MPEA) comprising nickel, iron, and manganese, offering promising advancements for energy conversion and storage. Using an integrated approach that combines direct ink writing (DIW)-based additive manufacturing with chemical dealloying, the team has established a foundation for efficient discovery and production of these unique materials, which have traditionally faced limitations in practical applications.

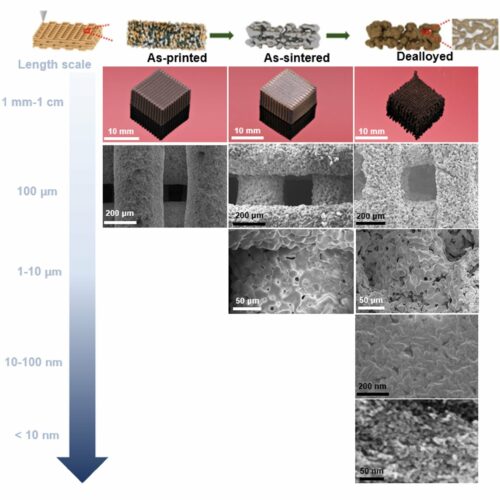

MPEAs, or metal alloys formed from the random mixing of multiple principal elements, display enhanced mechanical and functional properties over traditional alloys. However, their potential has been constrained by challenges in producing bulk samples with a nanostructured architecture and navigating the broad compositional space required for high-throughput discovery. Through the collaboration of these two research institutions, hierarchically porous NiFeMn MPEAs were developed, with composition tailored via adjustments in the starting metal powder ratios. This strategy significantly reduces the time required for dealloying, achieving efficient diffusion with multiscale pores that facilitate energy-conversion capabilities.

The innovation is particularly relevant to researchers in renewable energy, materials science, and electrochemical engineering sectors who are exploring ways to enhance energy storage and conversion. “The new integrated approach, which combines additive manufacturing and chemical dealloying, offers a transformative means of synthesising compositionally complex MPEAs,” stated the research team. Their method, coupled with machine learning-based simulation, allows for rapid exploration across the vast compositional space of MPEAs. This is crucial as the relationship between composition and performance is often non-linear and influenced by underlying phases and microstructures, making high-throughput material discovery a valuable tool.

One key case study in the research highlights the alloy’s composition-dependent performance in the oxygen evolution reaction (OER), which underscores its applicability to other electrochemical reactions vital for renewable energy, such as hydrogen evolution and oxygen reduction reactions. By offering control over composition and structure, this alloy synthesis method can enable targeted design of MPEAs for renewable energy applications.

The research presents a significant step forward in bulk fabrication of nanostructured MPEAs. Researchers anticipate this method will open avenues for further applications in energy storage and conversion technologies, pushing the boundaries of material science for a sustainable energy future.