Using electro-hydraulic actuators, this technology mimics biological muscle movements, offering enhanced adaptability and reduced heat generation.

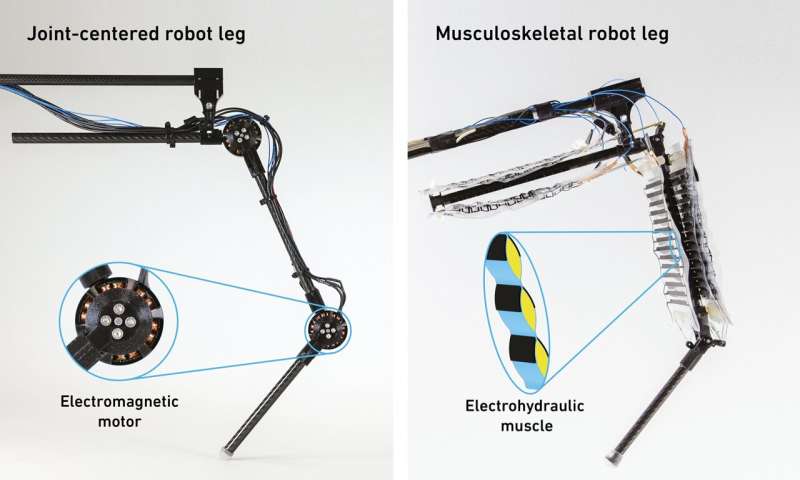

For nearly seven decades, robots have relied on motors—technology that’s been around for over 200 years—to power their movements. Despite advancements, these robots, including those designed to walk, have remained less adaptable than living creatures due to their reliance on motors rather than biological muscles. Now, a new innovation from ETH Zurich and the Max Planck Institute for Intelligent Systems (MPI-IS) promises to revolutionize robotic mobility with a muscle-powered robotic leg. This leg uses electro-hydraulic actuators, dubbed HASELs (Hydraulically Actuated Soft Elastic Actuators), to mimic the muscle movements found in humans and animals.

These actuators function similarly to balloons filled with oil, with electrodes that attract each other when a voltage is applied. This attraction causes the oil to shift, changing the shape of the actuator and simulating muscle contraction and extension. The key advantage of this technology is its energy efficiency. Unlike traditional electric motors, which waste energy as heat and require additional cooling systems, the electro-hydraulic leg maintains a stable temperature due to its electrostatic nature. Researchers found that conventional motor-powered legs consume significantly more energy and generate excess heat, making the new muscle-powered system a more efficient alternative. In addition to being energy efficient, the robotic leg demonstrates remarkable agility. It can perform high jumps and quickly adjust to uneven terrain without the need for complex sensors. Instead, its movements are controlled by simple input signals, which direct the actuators to bend or extend.

This simplicity allows the leg to adapt seamlessly to its environment, much like a human adjusts their posture when landing from a jump. The technology could enhance applications where high adaptability and energy efficiency are crucial, such as in grippers for delicate objects or future rescue robots. While the current prototype is limited to jumping in circles and attached to a rod, future developments aim to integrate this technology into more versatile walking robots. If successful, these advancements could lead to the creation of autonomous robots capable of navigating complex environments, paving the way for new applications in robotics.