Certified for functional safety in modern industrial and consumer appliances while addressing screen sizes beyond 10 inches

Home appliances connected to an internet network enable both users and manufacturers to comfortably communicate with each other, allowing a user of a kitchen oven to look up a new recipe online or a manufacturer to perform remote diagnostics or over-the-air firmware updates. Therefore, displays and touch sensors are essential for enabling this functionality in modern appliances.

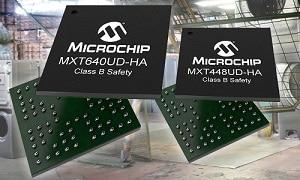

Facilitating this are two new Class B touchscreen controllers, the MXT448UD-HA and MXT640UD-HA from Microchip Technology that provide dedicated solutions for larger screen sizes as well as scalability to customers. In addition to Class B, these new devices are also compliant with the IEC61000-4-6 Class A specification for conducted noise immunity up to 10 Vrms (level three for industrial use), which enables products with a touch screen interface to operate in very harsh factory environments where electromagnetic interference (EMI) can be caused by conveyor belts, power rails or assembly machinery. This functionality also protects consumers using unprotected touchscreens on an oven or washing machine, from EMI due to unshielded power transmission, electric motors and neighbouring electrical equipment.

These new touchscreen controllers also come with serial interfaces such as SPI and I²C that operate simultaneously allowing redundancy in a design through the integrated safety features including individual communication between the touchscreen controller to the host microprocessor (MPU) in addition to a safety microcontroller (MCU). Touch events are provided to both processors at the same time. This unique architecture shortens time to market and reduces development cost by allowing all safety-critical firmware to be developed on a dedicated safety-certified MCU (with mandatory source code review by an IEC/UL test lab) separate from the main processor running the appliance’s Graphical User Interface (GUI).

“As products add more controls via a touch screen, the interface must work reliably to both satisfy and protect users,” said Clayton Pillion, director of Microchip’s human-machine interface business unit. “maXTouch technology delivers outstanding noise immunity performance allowing for safe and robust operation throughout its lifetime. We have worked closely with customers to deliver the first functional safety touch controller families and are seeing high adoption where noise immunity is critical to a successful product.”

In addition to the IEC compliances, the MXT448UD-HA and MXT640UD-HA family supports an operating temperature up to 105°C, which is a key requirement for cooktops and ovens where the Human-Machine Interface (HMI) system is near heating elements.

Microchip offers software to supplement the new controllers, including maXTouch Studio (development tool) and maXTouch Analyzer (production end-of-line test/inspection tool). Additionally, the general-purpose ATEVK-MXT640UD-A Evaluation Kit (EVK) is also available.

The ATMXT448UD-CCUHA1 and ATMXT640UD-CCUHA1 for home appliances are available in volume production and can be obtained from an authorised worldwide distributor or Microchip’s website.