- The CC-100 conformal coating thickness tester can measure the thickness of both the wet and dry conformal coatings.

- The CC-100 can measure the coating thickness directly on production boards in less than 5 seconds.

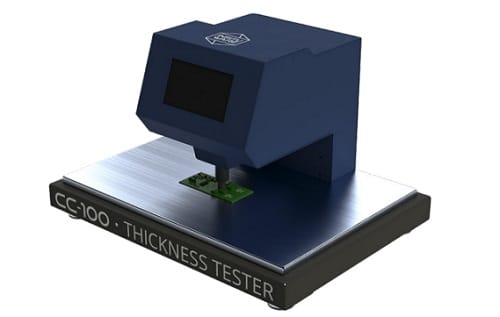

CC-100 from Insituware LLC is a Conformal Coating Thickness Tester measurement device. The CC-100 is capable of measuring the thickness of both the wet and dry conformal coatings directly on production boards in less than 5 seconds. The non-destructive and contactless testing method is fast and provides accurate results to help electronics manufacturers meet requirements for quality standards.

According to the company, the CC-100 Thickness Tester uses a chromatic confocal measuring principle to determine the thickness of transparent layers. The internal beam splitter uses white light to produce a spectrum of monochromatic light at varying distances away from the optical sensor. Light reflected from the top and bottom of a conformal coating layer corresponds to intensity peaks at individual wavelengths of light. The CC-100 uses the optical properties of a coating to determine the thickness of a conformal coating layer.

Dry Conformal Coating Thickness Measure the dry thickness of conformal coatings to verify against IPC-A-610 requirements. The CC-100 is easy to operate, therefore, skilled operator technique is not required for accurate and consistent thickness measurements. The machine can test various materials including acrylic, polyurethane, silicone, epoxy, and UV.

Features of CC-100:

- Rapid Measurement: Less than 5 seconds of measurement time

- Measure Genuine Assembly: Non-destructive and contactless technology eliminates the need for coating test coupons

- Easy Operation: Skilled operator technique is not required for accurate and consistent thickness measurements

- Statistical Process Control: Local and cloud data storage for traceability and process control

- Multi-Coating Support: Acrylic, Polyurethane, Silicone, Epoxy, and UV