IONETIC launched ‘an efficient blend of cost and customization’ to assist in speeding up battery pack development with a software-based platform that will uplift the energy density by 30 percent. IONETIC aims to provide this platform at low fees and low volume minimum order quantity, this will provide relief to automotive manufacturers to manufacture EVs at a lower cost. Hence, the transition to electrification and helping in sustainable development.

“There are many stages needed to get a battery pack into production. Automotive companies need to consider requirements, system design, homologation, embedded control, manufacturing options, and vehicle integration, to name a few. These stages are often done by different companies, which can lead to a costly, fragmented process. At IONETIC we facilitate all these stages, simplifying the process and reducing the cost for EV OEMs.” says James Eaton, CEO and co-founder of IONETIC.

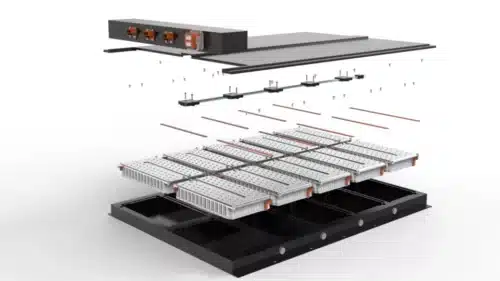

IONETIC claims that the ARC platform developed is customizable and provides an automatically optimized battery pack platform, its modules are customized automatically and the shelf modules are a fixed length so that vehicle must be configured around them, a 110cm space can fit two VDA390 modules but consist of a 32cm space empty that is not enough to fit a third. In a design exercise with an electric conversion company, IONETIC said it achieved an energy of 88kWh in the same space previously occupied by a 40kWh off-the-shelf system.

“We’re currently focusing on niche automotive companies in the UK and Europe,” says CEO James Eaton, “they typically make less than 10,000 vehicles per year, so probably don’t meet the minimum order quantities of large global battery pack suppliers, or can’t meet their high design fees.” Eaton continued “Gigafactories are mainly catering for mass-produced, cars. There’s a risk that some of these niche, historic car brands might not survive electrification unless companies such as IONETIC address their specific needs.”

Click here for detailed specification