Integrated real-time, sensor-free drive and control reduces power loss by 50 per cent and enables driving of 3x bigger motors

Featuring a unique, real-time, sensor-free control technology, TRINAMIC Motion Control GmbH has introduced two new sets of slot type, embedded motion control modules and development tools. These complete controller/driver modules keep the motor control system’s communications traffic low by processing real-time critical functions on-board and offloading demand on the system processor.

Featuring a unique, real-time, sensor-free control technology, TRINAMIC Motion Control GmbH has introduced two new sets of slot type, embedded motion control modules and development tools. These complete controller/driver modules keep the motor control system’s communications traffic low by processing real-time critical functions on-board and offloading demand on the system processor.

The control technology optimises the power drawn by industrial motors, reducing wasted power by 50 per cent and enabling the use of 3x bigger industrial stepper and brushless direct current (BLDC) motors (up to 7A).

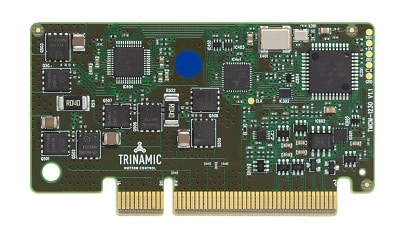

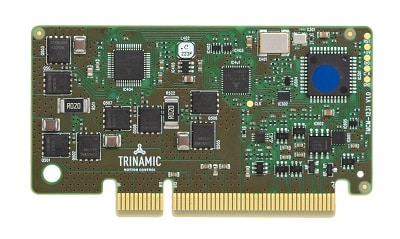

2-Phase Bipolar Stepper Solutions: The 5A RMS TMCM-1230 and 6.5A RMS TMCM-1231 are integrated single-axis controller/driver slot type modules. Each power 2-phase bipolar stepper motors and share the same form factor and pinout for easy exchange. Both modules employ Trinamic’s unique, sensor-free technology to detect the power demands of the motor in real-time and instantly adjust the current, reducing power by more than 50 per cent.

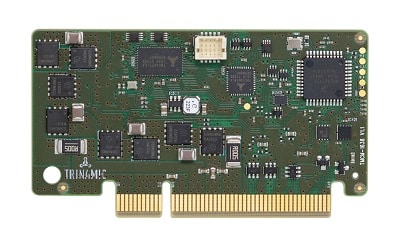

Field Oriented Control Solutions: Also offered are the 5A RMS TMCM-1637 and 7A RMS TMCM-1638 field-oriented motor controller/driver slot-type module that add Hall and ABN encoder capability for field-oriented control (or vector control). These modules support single-phase direct current (DC) motors, 2-phase bipolar stepper motors and 3-phase BLDC motors.

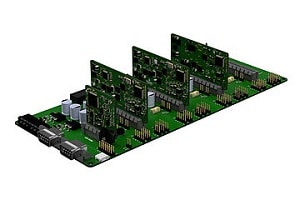

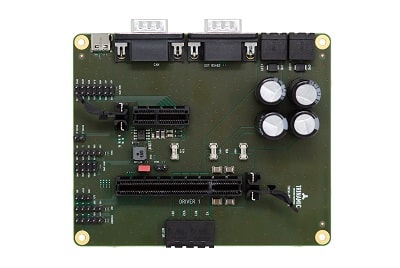

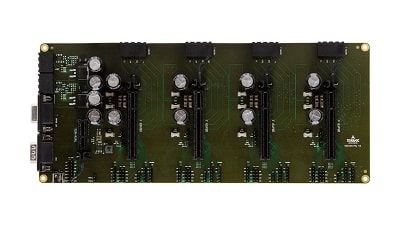

Free Integrated Development Environment (IDE): To rapidly evaluate system performance and speed time to market, design engineers can use Trinamic’s free IDE software together with the single-axis TMCM-BB1 or 4-axis TMCM-BB4 baseboards controlled with the TMCM-0930-TMCL microcontroller module.

Key Advantages

- Less Power and Cost to Drive Bigger Motors: Integrated critical control reduces compute demand on the processor while reducing wasted drive power by 50 per cent, permitting the use of larger motors.

- Easy Upgrade: The modules share the same form factor and pinout for easy exchange without rewiring to an external baseboard.

- Accelerate Time to Market: Intuitive integrated development environment helps the designer develop and test the system quickly.

“Offloading the processor of real-time critical calculations leaves processing power for other critical components driving intelligence to the edge, such as sensors, encoders, and cloud-based data transfers for status and health checks,” said Jonas Proeger, Director of Business Management at Trinamic. “Combined with the flexibility of a shared, swappable form factor, the modules offer an easy and straight-forward solution for powerful control of up to three times bigger motors.”

All products are available now from TRINAMIC Motion Control and Pricing and authorised distributors.