LiquidFlow2 is a cavity pump that operates without pulsation which enables it to apply very small beads and shots continuously and precisely.

The Meter Mix LiquidFlow 2 offers dosing accuracy of within ± 1%.

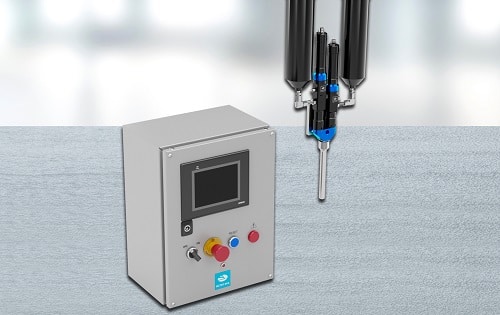

Meter Mix has released the LiquidFlow 2 cavity pump system for dispensing adhesives and potting compounds. It can easily dispense an extremely fine amount of potting compound precisely on the preprogrammed areas which reduces the wastage of the material and also the extra step of cleaning. The Liquid Flow 2 can be configured for either manual or robotic applications with a wide range of viscosities. The cavity pump can dispense very small and precise amounts of potting compounds which can reduce wastage and improve the efficiency of the application process. Unlike many other cavity pumps, the LiquidFlow2 operate without pulsation which enables it to apply very small beads and shots continuously and precisely.

A cavity pump system is used for dispensing very small and precise amounts of adhesives, potting compounds, and other similar materials. It is a type of positive displacement pump that works by trapping a fixed volume of material within a cavity and then forcing it out through a nozzle or dispensing tip. This type of pump system is ideal for dispensing fine and precise amounts of materials because it provides a constant flow rate and can be controlled accurately. Additionally, the cavity design helps to minimize material waste and reduces the risk of material contamination.

The compact metering and mixing system are configured for either manual or robotic application of two-component polyurethane, epoxy resin, silicone and methacrylate. The LiquidFlow 2 is configured with twin progressive cavity pumps, which can be manufactured from different materials. Therefore, the system can be utilised for processing abrasive and/or corrosive materials. The pumps operate without pulsation. Quantities from 0.006 millilitres can be dispensed with an accuracy of almost 99 per cent. The machine operation is user-friendly and takes place via an integrated PLC control system with a colour HMI touch screen. The LiquidFlow2 offers a high level of flexibility and allows for to store up to 50 different mixing ratios, flow rates, and shot quantities that can be stored via a recipe function. It also features an in-built anti-gel purge timer that prevents the material on the tip from curing in the disposable mixer nozzle.

The LiquidFlow 2 metering and mixing system is small & compact. It is suitable for automated applications in addition to bench-top mounting. It can even use abrasive and corrosive materials for specific applications making it a highly flexible solution for dispensing adhesives and potting compounds applications.