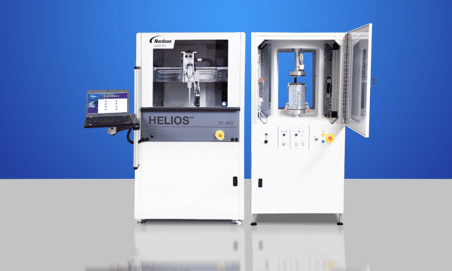

Nordson Electronics Solutions has recently introduced FS-EP1, a system solution for dispensing single-component thermal interface materials (TIMs). The system is developed by integrating the ASYMTEK Helios SD-960 Series fluid dispensing platform along with the FS-EP1 Fluid Supply/Feeding System. The Helios platform is capable of handling medium- and large-volume dispensing. The machine reduces material wastage and offers an easy-to-operate pail pump with a unique pail change and loading method. This device improves safety while minimizing downtime and material waste.

Single-component thermal interface materials (TIMs) are commonly used as gap fillers in electronics manufacturing. Facility air pressure and chunk pumps are commonly used to transfer these thick materials as the TIMs have a highly viscous and abrasive nature, making them difficult to feed from the original packaging to the dispense valve. Furthermore, low shearing of the material ensures that highly conductive thermal gap fillers do not separate, and material properties remain unaffected. The air pressure and chunk pumps are short-term solutions because the air pressure is often insufficient or the pump wears out faster, leading to premature failure.

According to the company, the FS-EP1 pail pump pushes material to the dispense valve using a closed-hydraulic system. There are no moving parts in contact with the gap filler, and no moving parts outside the pump enclosure, not even in the fluid line. The lack of moving parts makes high-performance bulk dispensing safe and easy to maintain while reducing downtime.

The company claims that to simplify the operation for the operators, the pump enclosure is designed in such a way that it securely holds a one-gallon pail at the operator’s waist level that making it simple to load and remove. Moreover, when it’s time to change out the pail, a semi-automated air-bleed routine with a priming valve ensures that air is removed from the system, operating behind the closed, safety-interlocked doors. Other features, such as the highly durable hydraulic pump, the intuitive operator interface, and the quick, tool-free seal changeover, establish new benchmarks in performance and maintenance. Helios dispenser processes are controlled by dedicated Fluidmove fluid dispensing software that includes user-programmable dispense geometries.