Onsemi’s ecoSpin family of Brushless DC (BLDC) motor controllers can simplify the development of high-voltage motor control systems.

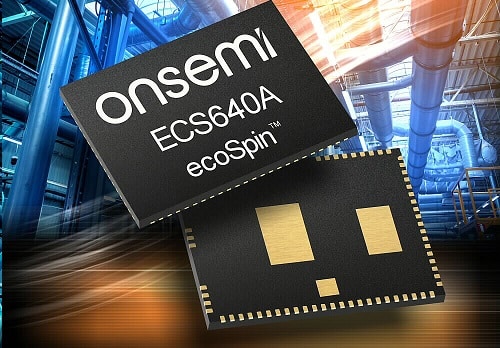

Onsemi has announced ECS640A, the first product in ecoSpin family of Brushless DC (BLDC) motor controllers. The ecoSpin motor controller family combines the controller and driver in a single product. The ECS640A can simplify the development of high-voltage motor control systems in applications such as heating, venting and air-conditioning (HVAC), refrigeration and robotics. The SiP is designed for reliable high-voltage operation of up to 600 V.

The highly integrated motor controller offers a smaller form factor, thus reducing size, development cost and time to the market. The ECS640A is powered by an ARM Cortex M0+ microcontroller, it also features three sense amplifiers, and three bootstrap diodes and can support both sensored and sensorless motor control architectures.

“The highly integrated solution reduces time to market by eliminating the need for design cycles on applications, simplifying solution reuse when scaling BLDC motor power level requirements,” said Michel De Mey, vice president of the Industrial Solutions Division, Onsemi. “Reliability is improved by replacing many of the larger, more complex devices, while at the same time shrinking the PCB routing area by approximately 20% compared to a discrete implementation, to deliver an overall compact solution.”

The ECS640A comes in a small package measuring just 10mm x 13mm, it enhances the performance while reducing the power consumption and noise. The motor controller IC enables rapid reuse in alternative platforms by simply changing the discrete power devices and updating the software. It supports traditional motor control techniques along with more advanced commutation algorithms which are available on the Cortex M0 platform. The use of different techniques allows for higher efficiency and improved control over the motor’s flux and torque over a wide speed range.