Texas Instrument’s ultrasonic lens cleaning (ULC) technology can create reliable, small and affordable cleaning systems for automotive and industrial applications that do not scratch the lenses.

The ULC system can automatically detect the type of dirt and use ultrasonic waves to clean the leans without requiring any human intervention.

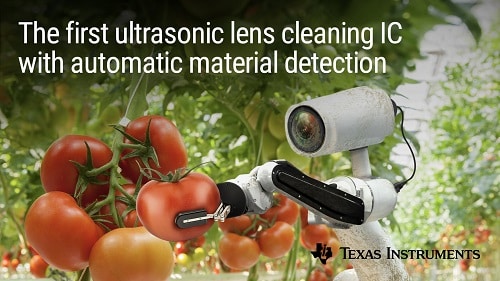

Texas Instruments have released the ULC chipset, the world’s first ultrasonic lens cleaning IC with automatic material detection. The ultrasonic lens cleaning (ULC) technology enables camera systems to quickly detect and remove dirt, ice and water using microscopic vibrations. This method not only keeps the camera lens clear of any dirt but also reduces the chances of any scratches that might come due to manual cleaning. Ultrasonic waves are sound waves that have a frequency above the range of human hearing, typically in the range of 20 kHz to 500 kHz. The chipset offers designers a compact and affordable way to use ULC in a wide range of applications and camera sizes. This cleaning technology will find a lot of applications in the upcoming vehicles which will require cameras, LIDAR sensors, etc.

TI’s new ULC chipset includes the ULC1001 digital signal processor (DSP) and companion DRV2901 piezo transducer driver. The ULC1001 controller includes proprietary algorithms for automatic sensing, cleaning, temperature and fault detection without any image processing, making ULC technology highly adaptable to various camera lens designs. The chipset’s small form factor makes it possible to improve machine vision and sensing in a variety of applications.

“As advanced driver assistance systems [ADAS] become more sophisticated and drivers rely on them more extensively, it will become more important than ever that the sensor suite is fully operational at all times,” said Edward Sanchez, senior analyst, global automotive practice, TechInsights. “Dirt or foreign material on a camera lens, which would be just a nuisance in the case of a rearview camera, becomes a vital functional and safety issue on a vehicle that relies on accurate and precise imaging and sensor data. TI’s ULC approach addresses what will soon be a significant issue in the ADAS and autonomous vehicle market both practically and cost-effectively.”

Ultrasonic lens cleaning can be very effective for removing dirt, dust, and other debris from camera lenses and other delicate items, as it does not require any physical contact with the item, reducing the risk of damage. Therefore, extending the lifetime and quality of the camera and Lidar sensors for a long duration.