A rolling transfer technique revolutionises optoelectronics by ensuring optimised properties of precise, tailor-made organic semiconductor films.

Organic semiconductors, typically made of carbon-based molecules or polymers, feature in numerous contemporary applications, such as ultra-slim, flexible, and lightweight thin films in modern transistors, sensors, and organic solar cells. The energy conversion capability and functionality of these films hinge on their electronic energy levels, influenced by the molecules, their arrangement, and interactions within the films.

Researchers at the Leibniz Institute of Photonic Technology (Leibniz IPHT) have developed a new method to produce these thin organic semiconductor films automatically with remarkable molecular precision. The technique aims to make films with controlled molecular interactions and designated energy levels.

Rolling deposition of semiconductor thin films

The rolling transfer method for Langmuir layers advances the traditional Langmuir Blodgett technique used for thin film deposition. This method is apt for creating monolayers of organic semiconductor molecules on air-water boundaries. A molecular layer formed on the water’s surface is moved onto a solid base.

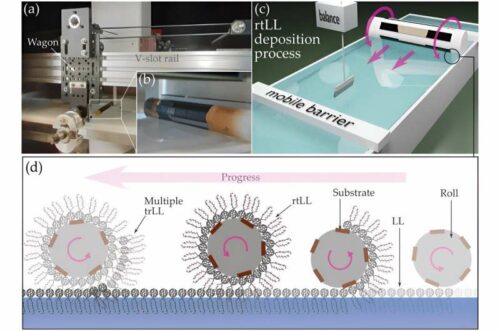

Researchers have developed a specialised rolling transfer system to deposit the molecular monolayer onto the substrate. This system holds the substrate meant for coating and is rolled over the molecular film on the water. During this rolling action, the molecular layer from the air-water boundary sticks to the substrate.

Tailor-made thin films

Two key factors are pivotal in crafting semiconducting thin films with customised structural and energetic attributes. Firstly, the rolling transferred Langmuir layer method permits systematic adjustments to the molecular packing density within a layer, which can range from highly compact to more loosely arranged based on the surface pressure during deposition. Secondly, the count of overlapping molecular layers, and consequently the film’s thickness, can be fine-tuned. This allows for the consistent production of semiconductor thin films with intended interactions between adjacent molecules and specific energy tiers.

The method devised by the researchers sets the groundwork for producing novel thin-film-based (opto-) electronic components with enhanced attributes.

Reference: Sarah Jasmin Finkelmeyer et al, Tailoring the Weight of Surface and Intralayer Edge States to Control LUMO Energies, Advanced Materials (2023). DOI: 10.1002/adma.202305006