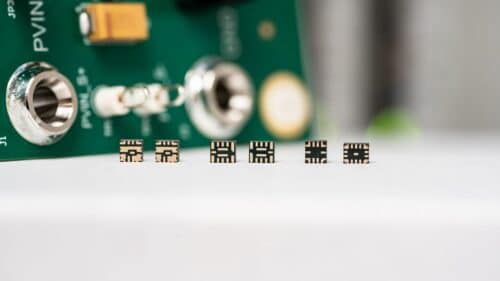

The six power modules reduce size by up to 23% and set new standards in power density for industrial and tech sectors.

Texas Instruments (TI) has launched six power modules that boost power density, enhance efficiency, and minimise electromagnetic interference (EMI). The company claims these modules are up to 23% smaller than their competitors. This size reduction enables industrial, enterprise, and communications designers to reach new performance levels. Notably, three of the new modules—the TPSM82866A, TPSM82866C, and TPSM82816—stand out as the industry’s most compact 6A power modules, delivering an unprecedented power density of nearly 1A per 1mm².

In the world of power design, compactness is crucial. Power modules streamline designs and conserve crucial board space by integrating a power chip and a transformer or inductor into a single unit. Texas Instruments MagPack packaging technology, through its exclusive 3D package moulding process, optimises the power modules’ height, width, and depth to pack more power into less space.

The magnetic packaging technology features an integrated power inductor crafted from a newly developed proprietary material. This innovation allows engineers to achieve unparalleled power density and reduce temperatures and radiated emissions while also minimising board space and system power losses. These advancements are particularly critical in settings like data centres, where electricity costs are a major concern, and some analysts forecast a doubling in power demand by the decade’s end.

“Designers turn to power modules to save on time, complexity, size and component count, but these benefits have required a compromise on performance – until now,” said Jeff Morroni, director of power management research and development at TI’s Kilby Labs. “After nearly a

Decade in the making, TI’s integrated magnetic packaging technology enables power designers to meet the defining power trend that has shaped our industry – pushing more power in smaller spaces efficiently and cost-effectively.”