This advancement not only promises higher energy density and efficiency for EVs but also paves the way for its application in robotics and logistics, marking a significant leap in sustainable energy solutions.

The future of electric vehicles (EVs) heavily depends on advancing efficient and fast-charging battery technologies capable of supporting long-duration operations. One innovative solution gaining traction is the development of structural batteries—batteries that serve dual purposes by acting both as energy storage systems and as integral structural components of the vehicle. Unlike traditional batteries that are added as external components, structural batteries are embedded directly into the vehicle’s structure, offering a more integrated and efficient design.

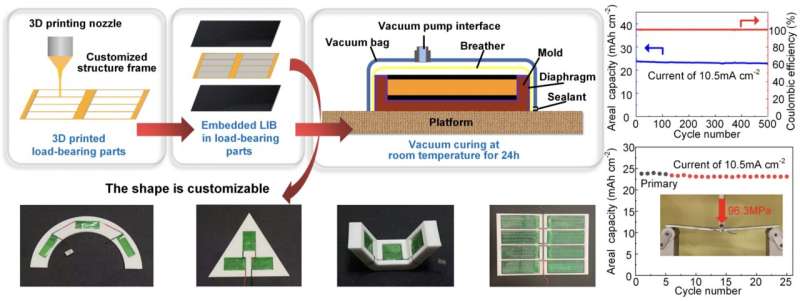

A recent breakthrough in this field comes from researchers at Shanghai University and their collaborators, who have developed an approach to creating high-performance structural batteries with customizable geometric configurations. This approach, detailed in a study published in Composites Science and Technology, enables the 3D printing of structural lithium-ion batteries tailored to various shapes and sizes. While previous attempts at creating structural batteries showed promise, they often suffered from low energy densities and poor electro-mechanical cycling performance. To overcome these challenges, Bao and his team employed a scalable fabrication strategy, leveraging the precision and flexibility of 3D printing. This technique allows for the creation of customizable structural frameworks that integrate energy storage materials, resulting in components that combine high energy density with robust load-bearing capabilities.

The implications of this technology extend beyond electric vehicles. The 3D-printed structural batteries could also be used in autonomous robots and warehouse logistics vehicles, showcasing the versatility and potential of this innovative approach to energy storage. “Our goal was to design an integrated energy storage and load-bearing structure with high capacity for both energy storage and mechanical load,” explained Yinhua Bao, the study’s corresponding author. He highlighted that material science plays a crucial role in this process, particularly in the synthesis and application of materials and the secondary design of components for energy storage. For example, frameworks made from carbon fiber or glass fiber can be adapted, and battery electrodes, separators, or electrolytes can be modified to enhance the performance of structural energy storage.References:Xu Ma et al, Customizable 3D-printed decoupled structural lithium-ion batteries with stable cyclability and mechanical robustness, Composites Science and Technology (2024). DOI: 10.1016/j.compscitech.2024.110783