Discover how researchers tackle the challenges of costly materials and production complexities, unveiling a scalable and affordable solution. With the potential to replace rare indium and pricey silver, this could be the future of mass-produced, efficient solar energy.

Silicon heterojunction (SHJ) solar cells, which form a junction between semiconductors with varying band gaps, stand out as one of the leading photovoltaic technologies. These cells have demonstrated excellent power conversion efficiencies and consistent operational stability.

While SHJ solar cells offer considerable potential and benefits, they often rely on scarce and costly materials, restricting their broad adoption. Additionally, their production often doesn’t align with current manufacturing techniques, posing challenges for mass production. However, researchers from Suzhou Maxwell Technologies Co., Nankai University, and other Chinese institutes have recently unveiled a novel design and fabrication approach. This method aims to make SHJ solar technology more affordable without significantly compromising efficiency. The team shared the results achieved with solar cells employing this new approach.

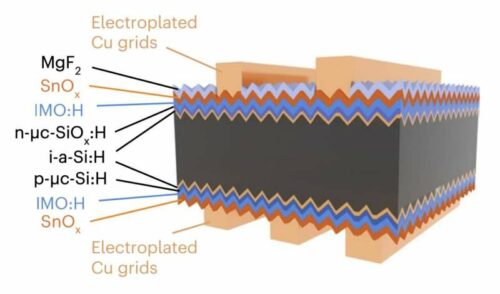

“One of the primary challenges for SHJ solar cells is the constrained availability of rare indium and the expensive nature of silver paste,” penned Cao Yu, Qiaojiao Zou, and their co-authors in their study. “Addressing the issue of indium-based transparent electrodes in efficient SHJ solar cells, we’ve effectively developed cost-effective, widely producible undoped tin oxide (SnOx) electrode materials, prepared via sputtering at ambient temperature.”

The research team created new transparent electrodes, crucial for SHJ solar cells, using undoped SnOx. They employed a scalable deposition method that aligns well with current production techniques. Preliminary tests revealed that these materials displayed highly beneficial characteristics, leading to outstanding performance in the team’s solar cells.

Leveraging its inherent oxygen vacancy defect, the crafted materials showcased a carrier mobility of 22 cm² V⁻¹ s⁻¹ and a resistivity of 2.38 × 10⁻³ Ω cm. Using an undoped SnOx as the front transparent electrode, the SHJ solar cell achieved an impressive 24.91% efficiency. The SnOx films possess superior chemical stability, resisting corrosion from acid and alkali solutions during electroplating. When SHJ solar cells were fabricated using a plated copper electrode and halved double-sided indium-based transparent electrodes, they achieved a certified efficiency of 25.94% over a total area of 274.4 cm².

This latest research by the team underscores the potential of using undoped SnOx as a substitute for indium and silver in crafting transparent electrodes for SHJ solar cells. Their innovative design maintains solar cell efficiency while significantly reducing production costs and complexities.

The latest discoveries might pave the way for further studies on the capabilities of the transparent electrodes they developed or those crafted from analogous materials. Such endeavours could expedite the mass production and market introduction of SHJ photovoltaics, which, while promising, have been challenging to scale up.