Researchers from Wuhan University of Technology have developed a novel strategy to boost perovskite solar cells’ efficiency, stability, and scalability, paving the way for more affordable and durable solar energy solutions.

Solar cells made from perovskites, a material celebrated for its exceptional optoelectronic properties, have recently achieved power conversion efficiencies (PCEs) on par with traditional silicon-based photovoltaics. With the added promise of affordability, these perovskite-based cells could revolutionize solar energy adoption. However, their sensitivity to environmental factors like heat, moisture, and UV radiation has hindered their durability, leading to performance degradation over time.

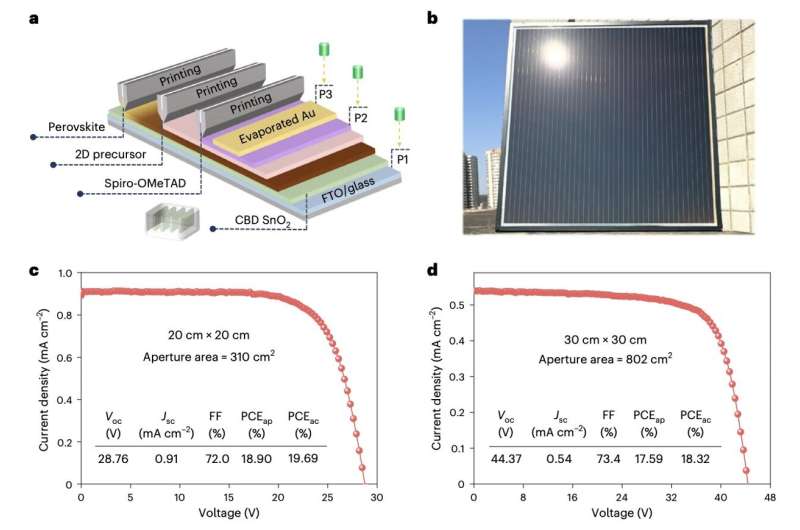

A potential solution lies in passivating the 3D perovskite light-harvesting layers with protective 2D perovskite coatings. These layers shield the solar cells from environmental stressors, preserving their efficiency and extending their lifespan. The researchers from Wuhan University of Technology and collaborators worldwide introduced an innovative method to create homogeneous 2D perovskite passivation layers. This strategy effectively overcomes challenges like phase separation and uneven coverage, issues that previously limited scalability and efficiency.

The results showed active-area efficiencies of up to 25.61% for small devices and 18.90% for larger, slot-die-printed modules. Moreover, these mini-modules demonstrated extraordinary durability, with operational stability exceeding 2,000 hours under continuous illumination.The proposed approach is compatible with existing printing technologies, making it viable for large-scale production. By enhancing both performance and stability, this development could accelerate the commercialization of cost-effective perovskite solar modules, bringing solar energy closer to widespread adoption.

“The formation of a homogeneous passivation layer based on phase-pure 2D perovskites is a challenge for perovskite solar cells, especially when upscaling the devices to modules,” the researchers explained. Their method involves treating the perovskite layer with formamidinium bromide and long-chain alkylamine salts, yielding a stable 3D/2D heterostructure.