Researchers at the University of Houston have invented a sensor capable of operating in temperatures up to 900°C or 1,650°F.

Extreme industries demand sensors for safety and system integrity. Petrochemical pipelines face varied climates, from scorching deserts to freezing arctic conditions. For example, nuclear reactors span 300-1000 degrees Celsius, and geothermal wells reach 600 degrees Celsius.

Researchers at the University of Houston have created a sensor that functions in extreme temperatures up to 900°C or 1,650°F, matching the heat of mafic volcanic lava, the Earth’s hottest lava type. Robust sensors are vital for efficient and reliable performance in extreme environments.

Making it work

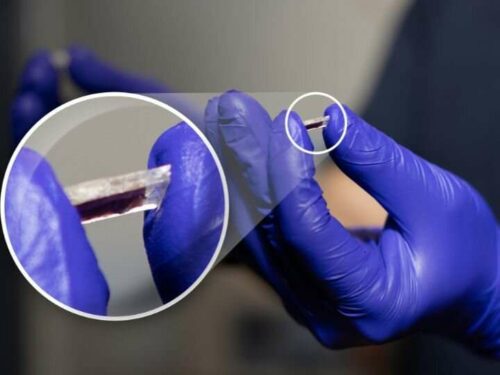

The team have developed GaN-based pressure sensors for harsh environments. It maintains sensitivity up to 350°C, slightly lower than lead zirconate titanate (PZT) transducers. To investigate the hypothesis, the team designed a sensor incorporating aluminum nitride (AlN) since they believed that the narrow bandgap, which refers to the minimum energy needed to stimulate an electron and facilitate electrical conductivity, was responsible for the observed decrease in sensitivity. The sensor confirmed the hypothesis, which achieved the highest operating temperature among piezoelectric sensors.

Despite AlN and GaN having advantageous properties for extreme environment sensors, the team was thrilled to discover that AlN exhibited a broader bandgap and a greater temperature range. However, they faced technical hurdles in synthesizing and fabricating high-quality, flexible thin film AlN. The researchers focused on piezoelectric devices and III-N materials.

What’s next?

After successfully showcasing the capabilities of AlN-based high-temperature piezoelectric sensors, the researchers plan to subject them to rigorous testing in real-world harsh environments. The researchers plan to utilize the sensor in harsh scenarios, such as neutron exposure and high-pressure testing in nuclear plants and hydrogen storage. Due to their stable material properties, AlN sensors can effectively function in neutron-exposed atmospheres and extreme pressure conditions.

The sensor’s flexibility provides added benefits, enabling its utilization in future applications such as wearable sensors for personal health monitoring and precise sensing in soft robotics. The researchers anticipate the commercial viability of their sensor in the future.

Reference : Nam‐In Kim et al, Piezoelectric Sensors Operating at Very High Temperatures and in Extreme Environments Made of Flexible Ultrawide‐Bandgap Single‐Crystalline AlN Thin Films (Adv. Funct. Mater. 10/2023), Advanced Functional Materials (2023). DOI: 10.1002/adfm.202370056

Always something new to know.

Thank you for your valuable feedback.