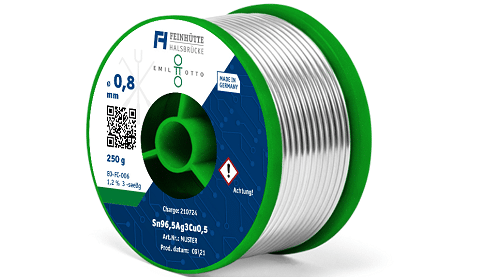

Emil Otto GmbH and Feinhütte Halsbrücke GmbH have released new flux-filled high-performance solder wires. These micro-alloyed solders are said to significantly reduce copper leaching and have an oxidation-inhibiting effect. The basis is two soft solder alloys filled with the newly developed flux compound EO-FC-006. The solder wires are optimized to reduce smoke and residue during the soldering process.

According to the company, both the wires have been tested on the equipment of Eutectic GmbH to check the smoke and residual behaviors of the wires. The solder wire AOX755 is a soft solder developed for the electronics sector, which consists of tin, copper, nickel, and germanium. This micro-alloyed solder significantly reduces copper leaching and also has an oxidation-inhibiting effect. The second alloy which is known as SAC305 is a standard soft solder consisting of tin, silver, and copper. It is one of the most common solders in the field of component production and cable assembly.

Both solder wires are provided with three cores of the specially produced flux EO-FC-006. The halogenide-free high-performance filler was specially developed as a flux filling for the production of lead-free soft solders. “The filling compound is based on a special synthetic resin in combination with a currently unique synthetic activation complex and thus meets even the highest qualitative production requirements to the highest degree. The activation effect of the filling compound is more than equal to the previous halogenide-containing filling compounds,” explains Markus Geßner, Marketing and Sales Manager at Emil Otto GmbH.

The testing of these solder wires has been done on a laser soldering test facility in Eutect’s technical center. “The interplay of chemical expertise regarding the composition of fluxes on the part of Emil Otto, the metallurgical know-how of Feinhütte Halsbrücke on the subject of solder alloys as well as our process knowledge with regard to selective soldering represent exactly the added value that our customers can expect from this cooperation,” says Managing Director Matthias Fehrenbach, describing the cooperation in the development of these new solder wire products.