Researchers at the National University of Singapore, the University of California and Nanjing University have developed a method to create soft textiles with electronic capabilities.

In recent times, researchers in the field of material science have been dedicated to the advancement of soft and flexible fibers with the potential to revolutionize the creation of innovative electronics. These versatile fibers hold the promise of applications such as smart sensing garments, energy solutions, and wearable biometric devices.

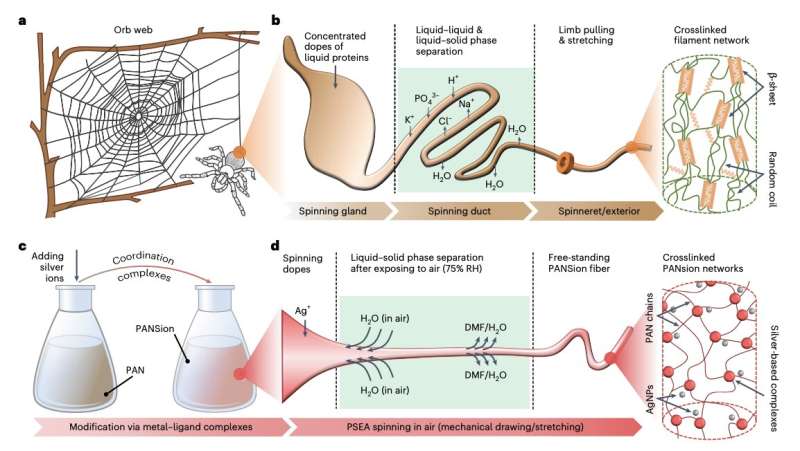

Researchers at the National University of Singapore, University of California Los Angeles (UCLA) and Nanjing University in China have introduced a novel approach for producing soft textiles endowed with electronic properties. Soft fibers enable smart textiles for energy, sensing, and therapeutic applications. Fabricating functional fibers is challenging, but our spinning approach, inspired by spider silk-spinning, utilizes spontaneous phase separation without needing high temperatures, excessive solvents, or complex systems.

The team created a solution of polyacrylonitrile (PAN) and silver ions in dimethylformamide (DMF). The silver-based complexes, known as PANSion, enhanced the spinning dope, enabling fiber spinning at ambient conditions. The solution’s silver ions are converted to silver nanoparticles (AGNP), allowing conductivity in the spun textiles. These fibers have the potential for smart textiles, thin energy devices, and wearable sensors. When spun into fibers, the researchers’ solution undergoes a spontaneous liquid-solid phase transition triggered by air and humidity, known as non-solvent vapor-induced phase separation (NVIPS).

By mimicking the silk-spinning process, a spinning solution of polyacrylonitrile and silver ions forms an elastic supramolecular network with silver coordination complexes and in situ reduced silver nanoparticles. The ambient-pressure, ambient-temperature approach produces mechanically stretchable (over 500% strain), strong (over 6 MPa), and electrically conductive (approximately 1.82 S m−1) soft functional fibers. The team validated the spinning technique by fabricating fibers used in two devices: a sensing glove and a smart face mask. They used a commercial glove as a substrate for the sensing glove and embedded their PAN-Sion spun fiber. The smart glove detected resistance changes when bent or exposed to cold and warm surfaces, converting them into signals transmitted to digital devices.

The researchers believe that fibers hold potential for various devices and wearable technologies. Moreover, their spinning technique and solution may inspire the development of similar approaches for functional fibers with electronic properties.

Reference : Songlin Zhang et al, Biomimetic spinning of soft functional fibres via spontaneous phase separation, Nature Electronics (2023). DOI: 10.1038/s41928-023-00960-w