ST ADG held a virtual media event on the future of automotive technologies. The spokespersons included Luca Sarica (Head of Strategic Business Development, ADG, STMicroelectronics), Davide SANTO ( Automotive MCU BU Senior Director, Division Strategic Office Member, ADG) and MH TEY ( Head of Asia Pacific Marketing & Applications, Automotive Products), STMicroelectronics. The focus was on ST’s strategy for automotive and elaborated on electrification and digitization of automobiles, software-defined vehicles and the future of vehicle efficiency & range with newer MCU platforms.

Moving Towards Electrified Vehicles

Today we are experiencing the transition from conventional to electrified and connected vehicles. The term electrified vehicle is not just restricted to electrically powered vehicles, but also the newer ICE engine vehicles, which happen to have a lot of auxiliary electronics systems, and powerful processors to control various functions of the automobile. This move towards electrified vehicles represents a major shift in the field, bringing very large business opportunities to semiconductor companies because in order to support this transition and enable features and functionality of the vehicle, the content of semiconductors in a vehicle is increasing at a blazing fast speed. It’s growing very fast. Just for reference, if we look at the bill of materials in terms of silicon in a conventional vehicle, we have the silicon content estimated to be at 500 dollars roughly. But if we repeat the same exercise for a new electrified and software-defined vehicle, the overall content will be 1,500-2,000 dollars per vehicle. So, it means the overall content is going up by a factor of three or four to a conventional car.

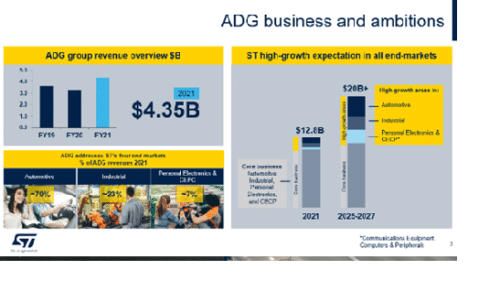

ST’s Automotive Discrete Group (ADG) is the main arm of STMicroelectronics that deals with the large majority of the overall automotive ST products. With the rapid increase in the adoption of EVs, ST expects higher revenues from automotive solutions. In the last year, 70% of the overall turnover came from automotive products, while 30% was from the sales of power solutions going into industrial and personal electronics. The EVs have two megatrends, the powertrain of an electric vehicle (EV) and autonomous driving.

“The large majority of the boost of our growth expected for achieving the twenty billion dollars plus- is coming from automotive.” Says Luca Sarica, Head of Strategic Business Development, ADG, STMicroelectronics.

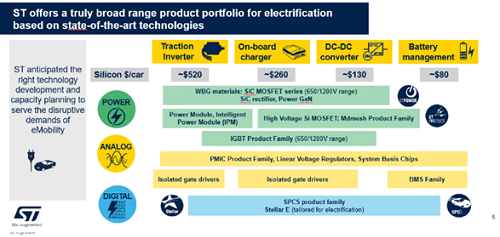

Powertrain of an EV

EVs have four major additional electronic modules over the ICE vehicles, these include a traction inverter, onboard charger, dc-dc converter, and battery management system (BMS). The quantity and cost of electronic components in each of these modules are quite high, and most of these additional electronic components are coming from power devices.

“Every application, every electronic module is using power solution for actuation (the muscles), and digital solutions are needed as the brain of every application. And the analog one is interconnecting the brain with the power stage for actuation applications,” Says Luca “In the domain of power, ST is offering a large offer of silicon carbide power modules and IGBTs that contribute to the reduction of CO2 emission of every vehicle, securing best-in-class performance for the electric traction, and for every stage of the power conversion that is needed in an electric vehicle. The other remarkable point is, in the domain of digitalization, as part of the Stellar unified digital platform of ST, we have a new family, the so-called Stellar E, microcontroller tailored for the digital power conversion systems that are used and needed in electric vehicles.”

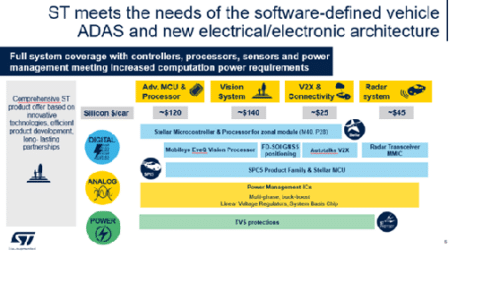

Software Platform

The other major component of modern vehicles is represented by the software-defined vehicle and the adoption of a new architecture in the car. The most important components which depend on semiconductors are the vision system, communication (V2X), and radar system. ST claims to have solutions for the digital, analogue, and power systems of automobiles.

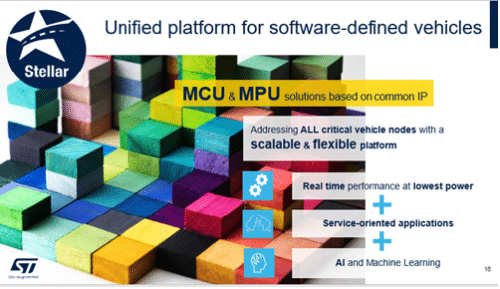

“We are addressing the brain of every vehicle.” Says Luca. “a unified digital platform called Stellar that is ranging from microcontrollers to microprocessors, making sure that we can address the needs of OEMs, and carmakers in addressing the new architecture, making sure that they could address the overall functionalities, they could connect the vehicle to the cloud, they could update the software, and they could run tailored software platforms according to their needs.”

Need for expansion of Semiconductors Manufacturing

The overall level of semiconductors in each vehicle is growing. The number of semiconductor chips used in an electric vehicle is higher by a factor of three or four than a conventional vehicle. This increase in the usage of semiconductors means that companies need to increase their production to meet the demands. It is extremely important to extend manufacturing for serving the growing demand else the prices of future vehicles will shoot up.

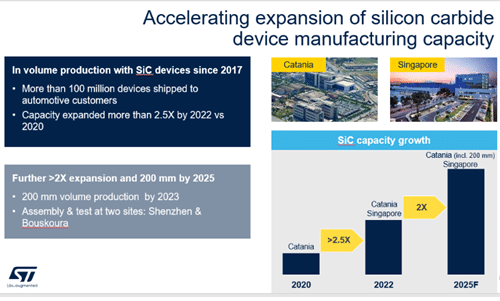

“ST is strongly committed in investing. We have a manufacturing strategy that is based on two main pillars. One is related to the expansion of our 300 mm production fabs.” At the same time, we are addressing software-defined vehicles, as well as e-Mobility. We are also investing a lot in our power manufacturing plants, especially in the wide bandgap solutions.”

Software Defined Vehicles (SDV)

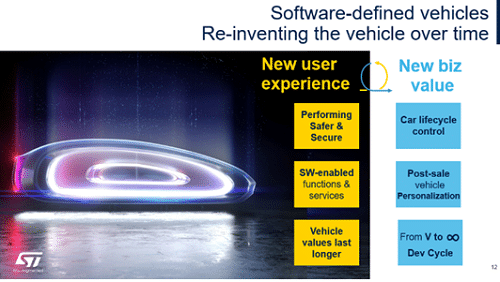

With the onset of EVs, automobiles are becoming smarter. These vehicles are not just machines with limited electronics, but rather software-defined vehicles. This new concept of software-defined is something that can be dynamically adapted, creating the possibility for users to enjoy more performances, meaning a safer vehicle, and more secure connectivity. They receive constant new functions and services of all types. Moreover, these vehicles are easier to upgrade, as the OEM can create and offer post-sales personalization without hardware changes. Which means additional and recurring revenue.

“Software-defined vehicles are not a new concept, but they are definitely changing and transforming the industry.” Davide Santo.

Engineers around the globe are currently focusing on three challenges that include enhancing the safety and security of both the vehicle and the passenger along with making a long-term future proof solution.

“Probably the most challenging aspect, is they need to be “future proof”, as OEMs want to go into a continuous cycle of development to create the recurring type of revenues. Therefore OEMs need to be able to have an underlying foundation, which is looking toward the future in terms of resources, flexibility, and capability to adapt to new challenges,” says Davide

The New Architecture of SDV

The new architecture of vehicles where all the sensorial and actuation devices living at the periphery of the vehicle will bring the data that will be aggregated and distributed to the central information and very high-level performing computing centre that will decide in abstract ways what to do and then deploy the actions. So, the fundamentals of software-defined vehicles are the possibility to have real-time data and power distribution managed in zone areas such that the idea of having the possibility to reconfigure with software the way a vehicle works and behaves is achievable.

“We created a platform called Stellar, which has some characteristics. It comprises MCUs for real-time objects and MPUs capable of application level. A vehicle lives in the real world and needs to break, steer, and accelerate in real-time, it allows the integration of different hardware and different software inside the same MCU. That means within the same MCU, we can have software applications that once were separated, including breaking software, steering software, and the body software, to live together on the same MCU.” Says Davide, he further adds “we have an adapted and advanced security and safety approach and can choose how many safety features are needed. We can choose which way and algorithms we will do with security. Dynamically, you can change this in time during the lifetime of the vehicle. Next, we have high-speed connectivity and routing capabilities. The data is the essence of a softly defined vehicle. We need to store, manage, and route data quickly and efficiently. Last but not least, we have what we believe is the most innovative and game-changing over-the-air update technology in the field.”

e-Mobility: The Future of Transportation

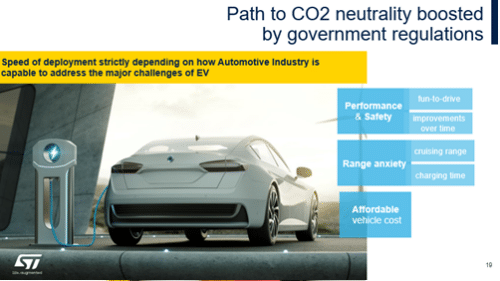

e-Mobility is one of the most discussed topics of this decade. The pace of development simply depends on how the automotive industry is capable to address the challenges, which include the cost, range and performance. No matter the type of vehicle, safety is the number one priority and hence we need to maintain both performance and safety. One of the roadblocks to higher adoption of EVs is range anxiety. Therefore, it is essential to design more efficient vehicles and charging infrastructure so that consumers can drive without fear of getting stranded in the middle of nowhere due to an empty battery. Last but not least, a large majority of people need to get value for money, therefore, look for a car that is comparable to the ICE engine cars and is affordable for them.

“ST has invested in fundamental technologies, like silicon carbide, in order to be prepared for this power changes, and we have state-of-the-art technologies. Silicon carbide is one. FDSOI, which is a specific technology for phase change memory, allows us to give best-in-class OTA. We provide solutions, not only technologies, and products.”

Advantage of SiC

When asked about the advantage of SiC over alternative solutions, David said that “ based on an industrial analyst report comparing the total cost of ownership of a carmaker using conventional solution (silicon-based) versus silicon carbide, the industrial analyst reported that the overall saving, in terms of the total cost of ownership, for the carmaker is in the range of 2,000 dollars when the carmaker adopts silicon carbide.” He further added “the silicon carbide is enabling the possibility to downsize the cooling system in the vehicle, representing a major burden, a major cost for the assembly of the car. At the same time, silicon carbide provides the possibility to downsize the battery while securing the same level of range versus conventional solutions. And an additional point is that the silicon carbide is helping to shrink the overall dimension of the board, reducing the overall cost of electric modules adopted in an electric car.” Those are the major contributors that are bringing the 2,000 dollars in savings mentioned by the industrial analyst, and this is the real reason why silicon carbide is so successful, and every carmaker is developing a new electric platform based on silicon-carbon solutions.”