The researchers from Sweden have developed silk-coated thread for energy-harvesting fabrics.

A research team led by Chalmers University of Technology (Chalmers), Sweden has pioneered a method for creating thermoelectric textiles capable of generating electricity. This innovation utilises ordinary silk thread coated with a conductive polymer, enabling fabrics to serve as energy sources for wearable electronics. Designed with health-monitoring sensors and mobile charging in mind, this silk-based technology could appeal to wearable tech developers, medical device manufacturers, and designers of smart garments, potentially transforming how we interact with everyday clothing.

Thermoelectric textiles convert temperature differences such as body heat versus ambient air into electrical current, eliminating the need for batteries or cables. The coated silk thread is safe, flexible, and non-toxic, making it well-suited for garments that sit close to the skin. “The polymers we use are flexible, stretchable, do not weigh much and are easy to use because they work in both liquid and solid form. They are also non-toxic,” explains Mariavittoria Craighero, doctoral student and lead author, Chalmers.

Initially, metallic components were required to stabilise conductivity in contact with air, but recent advancements now allow for silk threads made entirely of organic polymers. This innovation enhances durability and stability while removing the need for rare-earth metals, which are common in electronics. According to Craighero, “We found the missing piece in our thread—a type of polymer with outstanding stability and conductive properties, even in contact with air.”

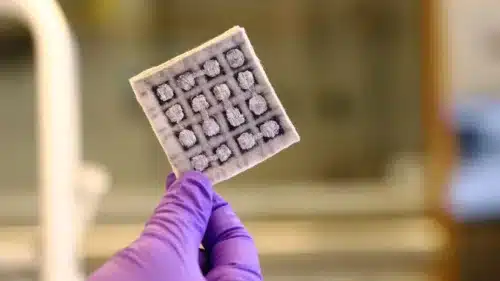

To demonstrate its practicality, researchers crafted two thermoelectric generators: a button and a textile patch embedded with the conductive thread. When placed between warm and cool surfaces, both generated measurable voltage. For instance, the textile patch produced about 6 millivolts with a 30-degree temperature difference, which could theoretically power small electronics when combined with a voltage converter.

Durability tests showed the thread retained two-thirds of its conductivity after seven washes, a promising result for practical applications. Although commercial production is currently challenging, as each piece must be sewn by hand, researchers are optimistic. Automation efforts are underway to accelerate manufacturing for broader use.

“We have now shown that it is possible to manufacture conductive organic materials that meet the needs of electronic textiles. This is an important step forward, and there are fantastic opportunities in thermoelectric textiles,” says Christian Müller, professor and research leader, Chalmers.

The findings emphasise the potential of organic electronics, as conductive polymers continue to gain interest across applications from solar cells to IoT and wearable technology.